In this article, NAPIT’s Bill Allan will consider how fixed RLV electrical installations are to be correctly tested.

Picture this. You are inspecting a reduced low voltage (RLV) fixed electrical installation supplied from a transformer which is centre-tapped to Earth (CTE) and has an output voltage of 110 volts. You discover there are two values of Ze, Zs, R1+R2 and Ip. No, you are not going mad. There really are two values of each of these characteristics. But which values do you measure? Which do you record?

Reduced low voltage (RLV) systems

Reduced low voltage (RLV) systems are addressed in Regulation Group 411.8.

BS 7671 defines a RLV system as; 'A system in which the nominal line-to-line voltage does not exceed 110 volts and the nominal line to Earth voltage does not exceed 63.5 volts.'

Three sources of supply are permitted for RLV systems (see Regulation 411.8.4.1).

The 5 second disconnection time

The protective measure for RLV systems is automatic disconnection of supply (ADS) and Regulation 411.8.3 requires that the earth fault loop impedance (EFLI), Zs must be such that the disconnection time does not exceed 5 seconds.1 Zs values can be calculated or the maximum Zs values in Table 41.6 can be used instead. The 0.8 factor must be applied to these values (see Appendix 14).

Table 41.6 shows the type of overcurrent protective devices which can be used.

The requirement of Regulation 411.8.3 for disconnection within 5 seconds pertains specifically to RLV systems which means that the disconnection times of Table 41.1 do not directly apply to RLV systems.2

RCDs

Where the relevant maximum Zs values in Table 41.6 cannot be met, an RCD may be required. 3 Some 230V RCDs will work at 110V but this needs to be confirmed with the product specification.

Fault protection

Fault protection must be provided by means of an overcurrent protective device in each line conductor or by an RCD (Regulation 411.8.3) 4. All protective devices must be suitable for use on 110 volts.

Testing fixed 110V installations

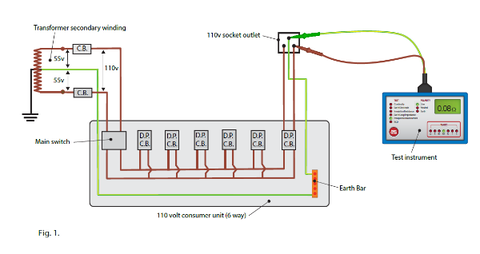

We will now consider the single-phase RLV system arrangement shown in Fig. 1 (at the top of the page).

Two Ze values

The secondary winding is the supply source and there are 2 line conductors. Consequently, there are two values for the external earth fault loop impedance, Ze . (This may be designated as Ztx , or something similar, to avoid confusion with Ze at the origin.) Theoretically, these two readings should be identical but, in practice, they can differ for a number of reasons. NAPIT recommends that both readings are taken but only the higher of the two readings recorded on the test certificate.

Two Zs values

It can be seen that there are two live conductors at the socket-outlet being tested with 110 volts between them.

Each line conductor is at a potential of 55V with respect to the earth terminal.

This means that two earth loop impedance (Zs ) readings have to be taken. It is recommended that both readings are taken but only the higher reading recorded.

Two Ip values

There are also two values of prospective fault current, Ip. Again, the recommendation is that only the higher reading is recorded.

Two PEFC values and two PSSC values

There are two values of the prospective earth fault current (PEFC) and one value of the prospective short-circuit current (PSCC).

In RLV installations, the PEFC and the PSCC are likely to be similar.

It is recommended that both values of the PEFC, together with the PSSC value, be obtained. The highest value should be recorded.

A double- pole circuit- breaker or RCBO should be fitted to the output from the secondary so that both poles disconnect simultaneously should there be a fault.

Two R1 + R2 values

There are two R1 + R2 values and again it is recommended that both values are measured but only the higher value recorded.

Measuring Zs

The Zs value can be determined using normal test equipment which is able to work at 110 volts. It is recommended that a two wire instrument be used as some three wire instruments require the neutral and earth to be at the same potential. Such instruments are not suitable for RLV systems because the neutral is not distributed.

Calculating the maximum Zs

The Zs value can be calculated and, where a circuit-breaker is used, Regulation 411.8.3 refers to the formula in Regulation 411.4.5 to calculate the maximum value of Zs.

There are more complex formulae that can be used but these are beyond the scope of this article.

Calculating the Ip

The prospective fault current Ip can be obtained by the following formula:

55

Ip = Zs

Conclusion

We hope this brief overview has answered some questions you may have had about RLV systems.

Prior to installing such systems, installers should familiarise themselves with the requirements in Regulation 411.8 of BS 7671.

The requirements of Part 6 of BS 7671 with regard to inspection and testing also apply to RLV systems.

Endnotes

- Some disagreement has arisen concerning the 5 second disconnection time. It is claimed that, under fault conditions, the touch voltage is unlikely to exceed 30 volts. This would put it within the extra-low voltage range which requires no disconnection.Be that as it may, disconnection is required to prevent fires and, because faulty systems should be disconnected and to comply with BS 7671.

- As the Zs values in Table 41.6 are obtained by multiplying the Zs values in Table 41.3 and Table 41.4 by 0.239 (55V ÷ 230V) and by 0.276 (63.5V ÷ 230V), there is a relationship between Table 41.1. However, only Table 41.3 (not Table 41.4) refers to Regulation 411.3.2.2 ,ie. Table 41.1.

- The requirement of Regulation 411.3.3(i) for RCD protection of socket-outlets with a rated current not exceeding 20A does not necessarily apply to 110V socket-outlets. See Regulation 704.410.3.10(i).

- All live conductors must be protected against overcurrent, ie. double-pole circuit breakers for single-phase circuits and triple-pole circuit-breakers for three-phase circuits.

As a NAPIT Registered Installer, you can access a wealth of technical information, guidance and advice.

If you would like more information on joining a NAPIT scheme, visit www.napit.org.uk or call 0345 543 0330.