Chaz Andrew, Technical Manager at Doepke considers how different types of residual current can impact on RCD performance and the reasons behind the requirements of regulation 531.3.3 proposed in the 18th Edition of BS 7671 IET Wiring Regulations.

The 18th Edition will include additional guidance on the use of specific types of RCD, based on the characteristics of the residual current - Regulation 531.3.3. We have produced this guidance in response to a number of requests to explain why and how different types of residual current can impact on RCD performance and the reasons behind the requirements of regulation 531.3.3.

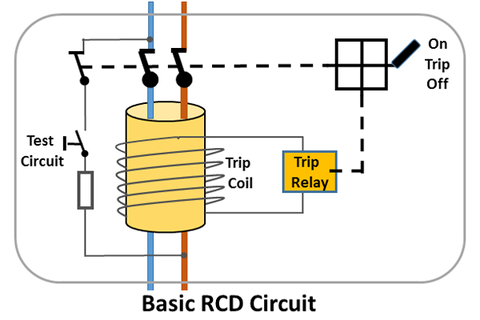

RCD Principles of Operation

The theory and functionality of RCDs rely on some basic electrical and physical principles, which most of us have probably forgotten (for instance the magnetic saturation of steel alloys!). Remember your copy of “Hughes”, it’s all in there (mutual inductance, transformer theory etc). The explanation below can be validated by going back to basics to prove it is correct, or we can accept that the regulations and advice are there for good reasons of safety and not just to make the installation more complicated.

Type AC RCD calibrated for 50 Hz supply

For Type AC 50Hz RCDs, the principles of operation* and the tripping accuracy are only applicable for 50Hz sinusoidal residual currents. Subjecting the RCD to a different frequency, waveform shape and/or DC residual current, will affect the tripping performance. High-frequency AC and or DC residual currents will saturate the magnetic circuit of a conventional AC RCD, preventing the generation of an emf in the trip coil. This phenomenon is explained in more detail below, along with some examples of common appliances and the types of leakage current associated with the appliance control function.

* Basic AC RCD function based on Kirchhoff’s 1st Law

* Basic AC RCD function based on Kirchhoff’s 1st Law

The current flowing in the live conductor, from the source to the load, will be equal to the current flowing in the neutral conductor, from the load back to the source. When these currents are equal and opposite, they cancel each other out i.e. the sum of the currents induced in the trip coil will equal zero. If the currents are not equal in the live and neutral conductors, an AC current proportional to the difference (residual current) will be induced in the trip coil. When this current reaches a predetermined value, the trip relay will operate and open the RCD contacts.

Why do different types of residual current affect RCD sensitivity?

The emf induced in the trip coil relies on the collapse of the field generated in the magnetic circuit as the primary current changes polarity and passes through zero. The hysteresis loop (B/H curve) and the quality of the steel used in the magnetic circuit must be suitable for the applied supply frequency. If the frequency of the AC residual current is too high, the magnetic field may not collapse fast enough before the current starts to increase in the opposite direction. The magnetic circuit becomes “saturated” and will not generate an emf in the trip coil.

Similarly passing a DC current through the primary side of an RCD, will magnetise the core, but will not result in the generation of an e.m.f in the trip coil, as the current is only in one direction. The magnetic core will be “pre-biased” by the DC component i.e. an AC residual current flowing in the circuit will not be able to generate an emf of sufficient value to trip the RCD, due to the effect of the DC component. This is explained and shown diagrammatically in Figure 1.

Original drawing Source: www.zvei.org with additional text added.

The Hysteresis curve 0 to B3 represents the +ve half of RCD magnetic circuit characteristic, with optimum operational area for reliable detection of residual currents, indicated by the green area. Yellow represents the area of increasing magnetic saturation, indicated by the flattening of hysteresis curve at points B2 to B3. If the RCD is subjected to 50Hz sinusoidal residual current IRac (I), equal to the tripping value sensitivity of the RCD, this produces a magnetic field 0 to B1 for the +ve ½ cycle. The resultant change in this field as IRac passes through zero for –ve ½ cycle induces a proportional voltage (II) in the trip circuit which is sufficient to trip the RCD.

If the same RCD is subjected to a residual current with +ve biased dc component IRdc > 6 mA, this will result in a shift for the operating point of the magnetic material on the H axis to the right. Now if a residual current IRac with the same value as (I) flows the combined current IRdc+ IRac (III) produces a magnetic field B2 to B3. Although the amplitude of (III) is similar to (I), the resultant voltage (IV) induced in the trip circuit winding is significantly lower and will not be sufficient to trip the RCD. This is due to the effect of the smooth dc content within the residual current, the RCD will be blind to the effects of an AC residual current.

If we consider a 30 mA type AC RCD it is calibrated on the bases of a residual current with a full sine wave content. Passing a type A residual current (1/2 wave 50 Hz) through it, will not produce the required magnetic field to trip the relay.

Regulation 531.3.3 Types of RCD

The Regulations state that the appropriate RCD, shall be selected based on the characteristics of the residual current, taking into account the different types of RCD and their limits of operation. This clause details the limits of operation for the various types, namely AC, A, F & B.

The use of Type AC RCDs in the UK for general purpose applications requires some consideration when designing or updating installations, as the majority of circuits now include appliances that can produce different types of residual current - see note 5 in clause 531.3.3. Additional information contained in BS 7671 Annex A53 Fig A53.1; gives examples of common semiconductor circuits contained in modern equipment, the associated residual current and the type of RCD required - see two examples below and associated diagrams.

Example 1 from Annex A53: Remote dimmer switch or simple motor speed control for a fan.

The power to the load is varied by switching the supply on and off at mains frequency, producing a pulsed 50 Hz current (IL). In the event of an earth fault (IF), the residual current that flows in the circuit will reflect the pulsed output of the mains i.e. requires the use of a Type A RCD upstream to detect the residual current.

Example 2 from Annex A53: Domestic washing machine with energy efficient motor control

Modern washing machines use brushless three-phase motors with inverter control, derived from a 230 V 50 Hz single phase supply. Vector-controlled algorithms for the various wash spin and drying cycles achieve the higher levels of energy efficiency required by the EU ecodesign regulations. During normal operation the load current (IL), taken by the inverter will be nonlinear, causing some distortion of the mains supply sinusoidal waveform.

In example 2, the location of the fault will determine the characteristics of the leakage current. A fault (IF1) located on the live output side of the bridge rectifier before the control stage, will produce a slightly distorted Type A residual current at 50 Hz. This residual current will also contain a smooth DC component, the value of which will be determined by the internal design of the inverter (value of the DC link voltage/capacitor). However, if we consider a fault (IF2) located at one of the input terminals of the motor, the nature of the residual current will be determined by the characteristics of the inverter output and the motor. IF2 will contain mixed frequency leakage currents, producing a composite leakage current that can cause saturation and or overheating of Type A RCDs, resulting in a loss of protection.

Type F RCDs are designed for use with appliances producing composite leakage currents with components from 10 Hz <50 Hz <1k Hz and smooth DC < 10 mA. Appliances with characteristics outside of this range should use Type B RCDs. The individual design characteristics of the inverter contained in the washing machine will determine which Type of RCD that can be used safely with the appliance. Consequently, the appliance manufacturer is responsible for specifying the installation and safety requirements for the appliance. If this information is not available when the installation certificate is completed, the Customer should be warned of the potential risk and a suitable note made on the installation report. In the event of a future accident and or fire related to the particular circuit, it can then be demonstrated that the risk was highlighted at the time when the certificate was issued.

18th Edition future-proof

Clause 531.3.3 states clearly the need to verify the selection of the RCD, based on the residual current characteristics of the load or loads connected to the protected circuit. This approach also has the benefit of future proofing the Regs with regard to protection i.e. as new appliances are introduced to the market, the selection of the RCD will be based on the residual currents that may be generated by the appliances.

For additional information on RCDs principles and selection, download Doepke Techpub-16.