A completely new type of earth clamp from Eaton MEM Circuit Protection and Control offers, it is claimed, significant advantages over traditional metal models:

Eaton MEM Circuit Protection and Control’s EZYBOND earth clamp achieves this principally by drastically reducing installation time but also through a superior connection and ease of cross-bonding. Contractors who have tried this new earth clamp have been impressed and believe that it could also reduce accidents on site.

EZYBOND Advanced Earthing Technology enables the installer to satisfy the requirements of BS 7671 (The IEE Wiring Regulations) for earthed equipotential bonding of gas, water and central heating pipes. It is suitable for single pipe bonding or cross-bonding of a number of pipes.

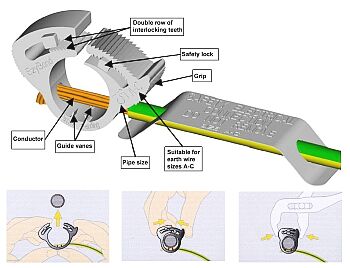

It uses a one-piece Nylon clamp to hold the bonding conductor in direct contact with the pipe. A conventional ‘SAFETY ELECTRICAL CONNECTION - DO NOT REMOVE’ label is provided.

Simple to install- dramatic reductions in installation time:

To install EZYBOND, the contractor cleans the pipe, as he would with a traditional clamp. He then strips at least 40mm of conductor from the cable, threads this through the safety label and then passes the exposed conductor through two holes in the back of the clamp, bending over the free end. The clamp is then hooked round the pipe and the two jaws are engaged, using finger pressure, and locked into position using gland pliers. The two jaws have a double row of serrated teeth that hold it firmly in place. A security lock ensures a tamper-proof connection.

In field trials, contractors have reported dramatic reductions in installation time compared with traditional earth clamps, resulting in substantial cost savings. It was also much easier and quicker to install EZYBOND earth clamps in difficult locations - for example under sinks and baths - where access and visibility are restricted.

Many other benefits:

The reduced risk, because there are no screwdrivers to slip and injure electricians, and the absence of sharp edges, were also highlighted with particular reference to risk assessment documentation.

However the benefits do not stop here: EZYBOND offers a direct copper-to-copper electrical connection and a secure, long-lasting mechanical connection.

EZYBOND clamps are moulded from heat- and UV-stabilised Nylon 6.6. This engineering polymer offers excellent mechanical properties, chemical resistance, heat resistance, self-extinguishing properties and freedom from corrosion. While the application to earth clamps is new, double-tooth clamps moulded from the same material have a proven track-record in other applications including the domestic appliance and automotive industries.

These new earth clamps are made in the UK and they have been tested at an ASTA laboratory to the relevant parts of BS 951:1999 Electrical Earthing - Clamps for Earthing and Bonding. They have also passed all the electrical tests and pull tests on the conductor. They have – in addition - undergone the resistance to ageing and resistance to humidity tests of BS EN 60669-1 and the resistance to heat and glow-wire tests of BS 1363-1.

The range of sizes:

EZYBOND clamps are available initially for pipe diameters 15 and 22mm. Each is available for two ranges of conductor size - Sizes A-C (2.5-6 mm2) and Size D (10 mm2). These are colour-coded black and grey respectively for ease of identification.

To summarise – the key benefits of EZYBOND are:

- Substantially reduces installation time.

- Superior electrical connection due to direct contact between conductor and pipe.

- Non corroding, heat-resistant and chemical-resistant, Nylon 6.6.

- Strong, tamper-resistant clamping action.

- Low risk on site - no screwdrivers or sharp edges.

- ASTA tested for electrical characteristics and conductor retention.

- Suitable for single pipe bonding or cross-bonding.

Field test 1 - Contractor's report:

The sample clamps had been received by our electricians with some suspicion and apprehension but after putting the product to use and understanding the ease of application, the reports back to us have been extremely favourable. In fact EZYBOND is now being requested as the preferred choice.

The installation time saved and the fact that no small components of the clamp can be lost will, without doubt, contribute to increased profitability ... the fitting will be correctly installed first time and will therefore not appear on a defects list as a loose or incorrectly installed earthing connection.

In our opinion it is a fine product that meets all the requirements. As fitting does not rely on the use of a screwdriver, the task can be classed as an 'Insignificant Risk' when compiling the contract risk assessment documentation concerning use of hand tools.

We have no reservations in recommending the clamp and will look forward to its use being the accepted method and standard of clamping onto pipework.

J Caldwell, Director,

Foster & Done Ltd.

Field Test 2 - Contractor's report:

...EZYBOND has been well received by both our Electrical and Mechanical installation teams and has also been received and approved by consultants and clients as an excellent alternative to the traditional earth bonding clip. EzyBond was especially advantageous to the installation teams working in the commercial and domestic installations.

Earth bonding became a quick and easy task and therefore labour-saving but still providing the same end result as the more labour-intensive traditional method. This use of EZYBOND and the labour saving that can be made by its use, can enable us as a company to become more competitive in an already competitive marketplace. This will in turn give added value to the end client.

As a company which holds Health & Safety as a priority, the actual tools required to install the EZYBOND in what are usually confined areas is excellent. There is no requirement for screwdrivers and so no opportunity for slippage and risk of injury to employees' hands etc.

...We look forward to seeing this simple but excellent product in the marketplace in the not too distant future.

(Lee Bromley, Estimating Manager

Cross Services Ltd.)

Contact: Richard Hunt

Eaton MEM Circuit Protection and Control

(Eaton Electric Ltd.,)

Reddings Lane, Birmingham B11 3EZ

Tel: 0121 685 2100

Fax: 0121 706 2012

Email: [email protected]