This article aims to provide clarity on issues surrounding joints and terminations in electrical installations.

Electrical connections (joints and terminations) are common within installations, both in live (line and neutral) conductors and in protective conductors.

The requirements relating to connections apply regardless of the voltage and therefore include extra-low voltage circuits. BS 7671 contains a number of requirements concerning the construction of electrical connections, to protect against the following dangers which could arise from a poorly constructed connection.

• Fire or other harmful thermal effects (due, for example, to excessive temperature developed in a high resistance connection when it carries current, or to arcs or high temperature particles emitted from a loose connection)

• Contact of a person or livestock with a live conductor at a connection (direct contact). Basic protection is provided to prevent such a contact.

• Fault conditions (due, for example, to a high resistance or open circuit connection in a protective conductor causing the earth-fault loop impedance of a circuit to exceed the maximum value required for automatic disconnection of the supply in the event of an earth fault). Fault protection is provided to prevent electric shock due to indirect contact.

Fundamental requirements

Every connection between conductors and between a conductor and equipment (such as switchgear, accessories or current-using equipment) is required to provide durable electrical continuity and adequate mechanical strength (Regulation 526.1 refers). Measures for protection against electric shock also have to be provided for connections in live conductors. Additionally, every connection in a live conductor or combined protective and neutral (PEN) conductor must be enclosed.

Apart from certain exemptions (listed in Regulation 526.3); all connections must be accessible for inspection, testing and maintenance.

Selection of means of connection and termination

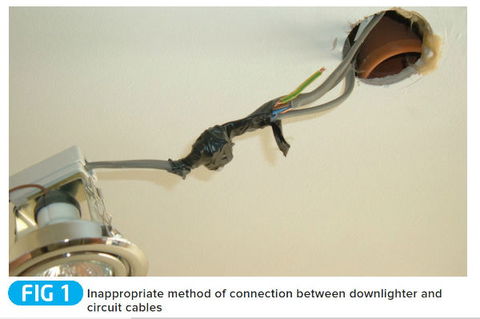

A means of connection between conductors, or between a conductor and an item of equipment, may take one of many forms, depending on the requirements of a particular installation. Examples of means of connection include a terminal of an accessory or item of switchgear, a terminal of a joint box, a connector block, a soldered or compression-type ferrule, and a soldered or compression-type lug bolted to a busbar. Fig 1 shows an example of bad practice in the connection of a downlighter to the circuit cables.

Whatever means of connection is employed; the list contained within Regulation 526.2 must be taken into account. In all cases, the limitations of equipment use specified in manufacturer’s instructions must be observed. Like any other parts of a wiring system, electrical connections must also be appropriately selected and erected as to be suitable for the external influences they are likely to encounter (Section 522 of BS 7671 refers).

The material of the conductor and its insulation

The material of a conductor and its insulation can influence the selection of a means of connection in various ways, some examples of which are as follows.

• An aluminium conductor must not be placed in contact with a terminal of brass or other metal having a high copper content unless the terminal is suitably plated (with zinc or cadmium, for example), or other suitable precautions are taken to prevent corrosion such as fitting a suitable ferrule to the conductor.

• Where an aluminium conductor and a copper conductor are joined together, precautions (such as plating) must be taken against corrosion.

Where an aluminium conductor is to be connected to a terminal, ferrule or lug, precautions must be taken to ensure that no undue mechanical pressure can be applied to the conductor, for example by the over tightening of a clamping screw.

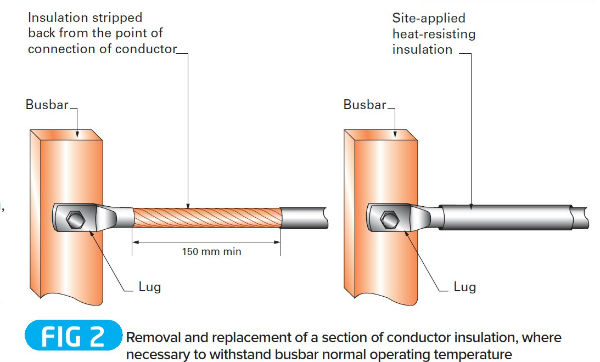

Conductor insulation must not be subjected to temperatures exceeding its rated value in normal service.

Particular attention is needed where conductors insulated with materials of different temperature ratings, such as thermoplastic (pvc) and thermosetting (XLPE or rubber), are to be connected (see Fig 2).

For example; the rated temperature of the insulation at the joint must be not less than the highest of those for the conductor insulation, or the conductors must be sized such that their normal operating temperatures will not exceed the lowest rated temperature of any of the insulating materials.

Enclosure of connections

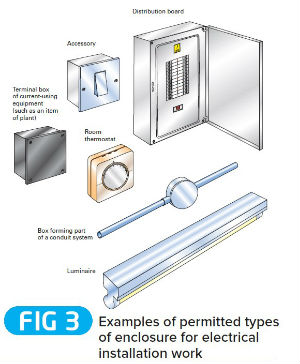

Irrespective of nominal voltage, every termination and joint in a live conductor or PEN conductor is required to be contained within an enclosure selected in accordance with Regulation 526.5 (See Fig 3). This includes connections in extra-low voltage circuits such as those supplying extra-low voltage luminaires.

The purpose of such an enclosure is to protect persons, and property against harmful thermal effects, such as arcs or high-temperature particles which may be emitted from a loose connection (Regulation 421.1.3 refers).

The enclosure may also provide basic protection against electric shock and protection against external influences.

For other guidance and publications please see the ELECSA website. Information about the ELECSA Domestic Installers schemes, visit www.elecsa.co.uk