In this article, the technical experts at ELECSA explore the concept of switching off for mechanical maintenance.

The term ‘isolation and switching’, as used in BS 7671, embraces four distinct concepts, each with its own particular requirements for safety. The four concepts are isolation, switching off for mechanical maintenance, emergency switching and functional switching.

The purpose of switching off for mechanical maintenance is to enable non-electrical work to be carried out on the switched circuit or equipment in safety by persons who may not be electrically skilled.

Mechanical maintenance is defined as the replacement, refurbishment or cleaning of lamps and non-electrical parts of equipment, plant and machinery.

Purpose

Switching off for mechanical maintenance is to enable non-electrical maintenance to be performed safely without the risk of burns or injury from mechanical movement. The demands of safety are such that in most cases the same means of preventing unintentional or inadvertent reclosing of the switch must be provided as are required for isolation. The enclosures of electrical parts of equipment are intended to remain in place during mechanical maintenance. Injury could result from burns from heating elements or some types of lamp or from mechanical movement such as might be caused by electrically-actuated machinery. For example, the safe replacement of a belt between an electric motor and a machine should be possible after switching off for mechanical maintenance. Switching off for mechanical maintenance is not intended to provide protection against electric shock; for this purpose a means of isolation must be provided in accordance with Regulation 537.2.1 .1 .

Persons

Switching off for mechanical maintenance is provided for the benefit of persons who are not necessarily electrically skilled and who may not necessarily be competent to avoid the dangers which electricity may create. Great care must be taken, in the design and implementation of measures for switching off for mechanical maintenance, to ensure that they provide safe working conditions, particularly where non-electrically skilled persons are likely to be undertaking the maintenance.

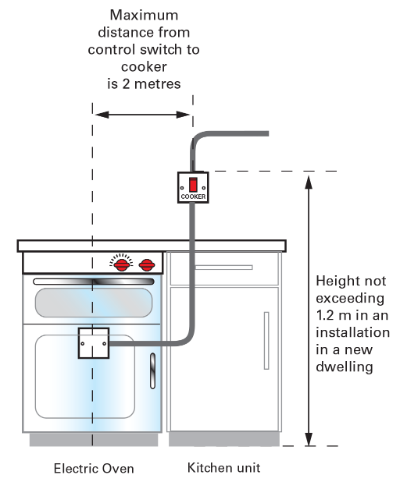

For example, Regulation 537.3.1.1 requires a means of switching off to be provided for a cooker, so as to facilitate mechanical repair or cleaning.

Fig 2 - Cooker switch

A cooker switch can perform the function of switching off for mechanical maintenance, providing the switch, is located so that it is continuously under the control of the person undertaking the maintenance task. As shown in Fig 2, generally, this is achieved by locating the switch within 2m of the cooker.

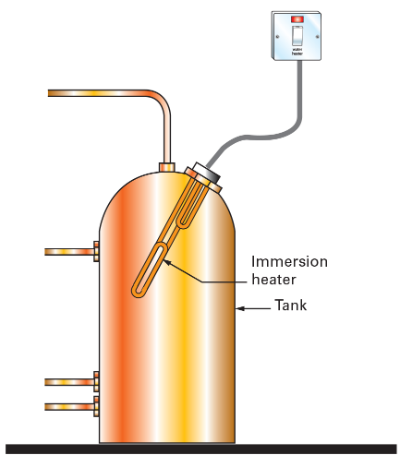

Fig 3 - An immersion heater with switch

A similar situation arises where, typically, a double-pole switch is installed next to an immersion heater. The switch disconnects the supply from the heater element and gives the person working on the water heater control of the supply. As with the cooker switch, this 'plumbers' switch must be situated such that it is under the continuous control of the person carrying out the work.

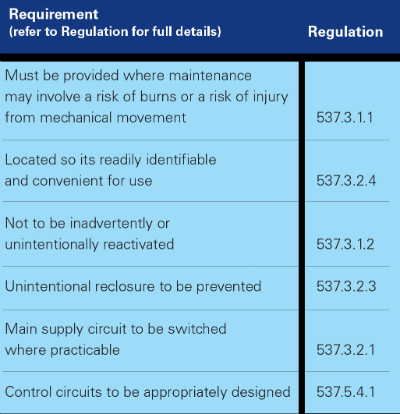

Summary of requirements for switching off for mechanical maintenance

For other guidance and publications please see the ELECSA website.