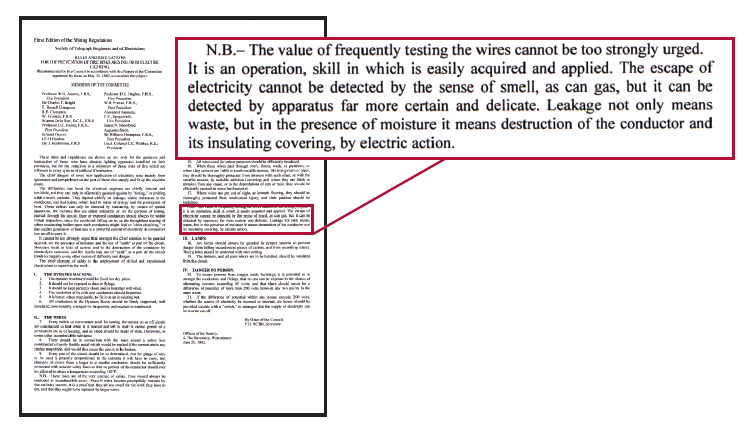

Even then it was recognised that testing was an important element in determining whether an electrical installation was safe to put into service; it states, ‘The difficulties that beset the electrical engineer are chiefly internal and invisible, and they can only be guarded against by ‘testing’ or probing with electric current’.

The development of the inspection and testing regime slowly developed throughout the 19th and 20th centuries such that by the introduction of the 14th Edition of the IEE Regulations for the Electrical Equipment of Buildings in 1966 there were four areas of testing that were recognised:

- Verification of polarity

- Tests of effectiveness of earthing

- Insulation resistance tests

- Test of ring-circuit continuity.

For those of a certain age, the acronym used as an aide-memoire for the testing requirements of the 14th edition was PEIR. The range of tests required were a mixture of ‘dead’ and ‘live’ tests and there was no specific requirement that any results were recorded. Indeed, once a new installation had been completed and inspected and tested a simple ‘Completion Certificate’ was to be issued to the client.

In the 14th edition of the ‘Regs’, where a periodic inspection and test was carried out an ‘Inspection Certificate’ was to be issued and given to the person ordering the inspection; again, there was no requirement that a record of the results was created, but at least a form had to be issued. The introduction of the 15th Edition of the Wiring Regulations in 1981 also introduced more detailed inspection and testing requirements. A new electrical installation now had a range of tests to be completed in a set order:

- Continuity of ring final circuits and circuit protective conductors and bonding

- Resistance of earth electrode(s)

- Insulation resistance and insulation of site built assemblies

- Protection by electrical separation and barriers or enclosures

- Polarity

- Earth fault loop impedance

- Operation of RCDs and fault voltage operated devices.

As with the 14th edition of the ‘Regs’, the range of tests included both ‘dead’ and ‘live’ tests. The significant change from the inspection and testing requirements of the 14th edition of the ‘Regs’ was in the recording of results. The certificates became more detailed and the contractor had to ensure actual values measured were recorded. The current format of many of our schedules of test results can be seen from the introduction of the 15th edition of the ‘Regs’.

By the time the 16th and 17th Editions of the Wiring Regulations had been introduced the Wiring Regulations became a British Standard, but the inspecting and testing regime became more detailed and the certification requirements became ever more detailed.

In the current version of BS 7671 (17th Ed inc. Amd 3) the range of tests include both ‘dead’ tests, such as continuity of protective conductors, insulation resistance and polarity, and a series of ‘live’ tests, such as RCD and earth fault loop impedance (although the latter can be checked by an alternative to measurement – see Regulation 612.9). The range of tests listed within the 17th Ed, whilst being more detailed, has not grown to any significant extent.

However, what is really causing a wide ranging discussion within the industry is not really the range of tests and the fact that the results have to be recorded; rather it is the seemingly never-ending list of inspection items detailed in Appendix 6 of BS 7671.

The model ‘Schedule of Inspections (for new installation work) for Domestic and Similar Premises with up to a 100 A supply’ falls under eleven sections headed:

- Distributor’s/Supply intake equipment

- Parallel or switched alternative sources of supply

- Automatic disconnection of supply

- Basic protection

- Additional protection

- Other methods of protection

- Consumer unit(s)/Distribution Boards

- Circuits

- Current-using equipment (permanently connected)

- Location(s) containing a bath or shower

- Other Part 7 installations or locations.

The intent of the model form detailing over sixty inspection items is to take the person carrying out the inspection on a bit of a journey starting, as it were, from the start of the installation through to the end of it.

The inspector, therefore, begins at the supplier’s/distributor’s equipment, including alternative supplies such as PV installations. He/she then should look at the means of basic, additional and alternative methods of protection against electric shock. The inspector then looks at the consumer unit and the circuits that it supplies and the connected current-using equipment. Finally, he/she is to consider the effects of special locations, such as rooms containing a bath or shower.

The current inspection regime, therefore, is little changed from that which went before; it simply encourages the conscientious contractor to record that which he/she was already doing. Embracing the change to the inspection schedule introduced by the 17th Ed. will not, therefore, require any significant change in thinking from the inspector, rather it will enable him/her to provide to their client, and subsequent inspectors, a clear and robust record of inspection.

- For other guidance and publications please see the ELECSA website.

- For information about the ELECSA schemes, visit www.elecsa.co.uk or call 0333 321 8220