You’ve probably heard of smart homes, but what about smart power drills? The IoT is permeating through the construction industry, not just in the systems you are installing, but also in the tools and equipment you use every day.

One of Voltimum’s key objectives is to provide readers with information and ideas on how IoT devices and smart solutions can improve the way electrical contractors can run their business. Usually, this comes from an installation perspective, looking at smart homes and business controls. However, the IoT is starting to pervade across all aspects of construction, even into the tools and equipment that you use on a daily basis.

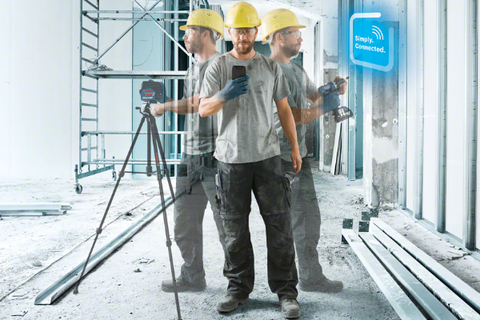

Connected power tools

All of our household electrical items are becoming connected, from our heating to our toaster. So the introduction of connected power tools should come as no surprise.

At its Blue Innovation Summit in June last year, Bosch Professional Power Tools unveiled a new stable of products that users can communicate with wirelessly using their smart device.

The Bosch Tool Box app allows the user to remotely control the various tools, setting and saving custom configurations so that work remains consistent and efficient. The app also gives you the ability to monitor the performance of their tools, with the app providing clear information about when and for how long the tool has been used and offering tips for troubleshooting any problems.

For example, the latest drill and driver ranges have several functions that communicate with the app to help prevent injury to the user and damage to the tools themselves. You can set the ‘KickBack Control’ function to trigger early via their smartphone reducing the risk of potentially harmful, sudden torque reactions in bind-up situations. Users will also receive warning messages via the app when the motors of their tools have stopped, for instance, due to overheating, so you don’t push your kit too hard and risk damaging it.

The benefits can also be seen with the laser measurement range. Where the latest combi laser features a rotating mini-tripod, so you can control the measure remotely even if you are on the other side of the room or halfway up a ladder. No need to keep returning to the tool to make adjustments.

Safer testing

Testing equipment manufacturers have also started building wireless remote control functionality into their devices as well as adding a few application-specific functions that should appeal to contractors and in-house maintenance workers.

American testing specialists Fluke has clearly developed its Fluke Connect concept with facilities managers in mind.

The Connect is a system of wireless test tools that report to a single dashboard-based software solution. The tool  range includes installation testers, digital multimeters, clamp meters, infrared cameras, insulation testers, oscilloscopes and power quality analysers.

range includes installation testers, digital multimeters, clamp meters, infrared cameras, insulation testers, oscilloscopes and power quality analysers.

By connecting the tool to the app or dedicated software, you can set up multiple tools to carry out multiple tests and then step back and record the findings. You can then store the findings and share with colleagues and clients.

The software the user chooses to run alongside the tools depends entirely on the level of analysis they would like to carry out. The simple app allows them to record measurements, store them in the cloud and tend and monitor intermittent problems.

The more advanced monitoring software package gives you the ability to build and sustain a preventative maintenance programme, saving measurement direct from the measurement tool, assigning them to assets in your facility, enabling you to prioritise your preventative actions.

The ability to accurately monitor installations and share measurements in real time is appealing but the safety benefits of this system cannot be overlooked either. By testing remotely, you can remove yourself from live electrical installations when carrying out the tests, recording measurements safely away from arc flash zones and other dangers.

Wearable technology

Already popular in the consumer arena, wearable tech, like the FitBit, is offering health conscious users the ability to track their activity like steps, heart rate and sleep, providing tangible data for them to benchmark their lifestyles and provide measurable goals to improve their health.

Snickers Workwear's adoption of wearable technology is also focussed on health and wellbeing concentrating health & safety the working habits of tradespeople. Tracker-1 is the prototype wearable product developed by the brand to help tradespeople– who work many hours in challenging work environments that put great pressure on their knees and hearing – stand a better chance of preventing workplace injuries.

Snickers’ market research for the product quizzed 530 tradespeople in the brand’s native Sweden, and in neighbouring Norway, on occupational health and safety.

The results revealed that more than one in two workers considers that not enough attention is paid to protective equipment at the workplace (52% in Sweden and 64% in Norway).

Six out of ten have suffered damage resulting from incidents at their workplace in the past year. This means that six out of ten are suffering from physical health issues or pain. The most common pain a worker suffers from is in the knees and back. More than 60% of Swedish and Norwegian workers suffer from this (63% in Sweden and 66% in Norway).

Attitudes at the workplace represent the main reason why available protective equipment is not used, according to more than every third respondent in both countries.

Overall, they concluded that overcoming occupational injuries requires a change in behaviour in the workers, prioritising health, personal safety and working efficiency over on-site “macho culture”.

Tracker-1 has been developed to challenge these attitudes and help facilitate this change. The device, which simply clips onto the users work trousers, contains a meter that measures noise levels, number of knee impacts per day and temperature. All the meter values are read by a mobile app, providing the user with feedback on their activity, helping them make informed decisions about preventing workplace injuries.

No job is worth sacrificing your health and well-being. Wearable tech like the Tracker-1 can help ensure you avoid causing any lasting damage to your body so you can enjoy your downtime with your family free of pain and discomfort.

Is it worth it?

“But what if I just want to drill a hole?” I hear you ask.

A valid point.

At the moment connected items come at a premium and no one could blame you for dismissing the addition of connectivity to a power tool as a gimmick. It may be hard to see the value of these innovations immediately but to truly see the benefit from all that the IoT has to offer you need to look past the idea of it as a costly gadget. The majority of IoT devices have been designed, in one way or another, to improve efficiency and make a task easier for the user.

Smart meters in our homes are a prime example. Simply having one installed isn’t enough. You need to engage with the meter and take the time to really understand the data it provides. Doing so can help you drastically improve your energy efficiency and negotiate better rates from energy providers. Similarly, smart tools and connected wearables are designed to ensure the user is working efficiently and as safely as possible, so you can work smarter, not harder.