Explore why relay protection testing is becoming more complex with IEC 61850 systems, and discover practical steps to streamline your protection workflows.

If you’ve been in protection testing for a while, you’ll know the job has changed – not always for the better.

Where once you could trust familiar test routines and steady equipment, today’s relay protection workflows are under pressure. New schemes. More devices. Less time.

More eyes on every report. Even experienced engineers are spending more time navigating admin, digging through configuration files or battling non-standardised setups, while trying to keep systems safe and compliant.

If you work in the field and feel squeezed by time or tools, support commissioning under tough conditions or want better results without an over-complicated solution, this blog is for you.

Here’s why things have become more difficult, and what you can do to reclaim time, consistency and control.

The perfect storm: Why everything changed at once

More complex protection schemes, less time to test them

Modern substations don’t look like they used to. IEC 61850, mixed IED fleets and DER tie-ins make the protection landscape more intricate. That means:

More logic to validate

More documentation to manage

More potential points of failure

Yet test windows haven’t grown. If anything, they’ve shrunk. You need ways to move fast without cutting corners.

The renewable energy integration challenge

Renewable energy integration has fundamentally changed how protection systems behave.

Engineers now face:

Bidirectional power flows that legacy relay settings weren’t designed for

Variable fault contribution from inverter-based resources that can confuse traditional overcurrent protection

Intermittent generation patterns that create protection coordination blind spots

New protection requirements for anti-islanding and grid support functions

This isn’t just theoretical. We’re seeing utilities scramble to update protection schemes that worked perfectly for decades but now trip unexpectedly or fail to operate when needed.

The cybersecurity layer nobody asked for

Digital relays brought us flexibility and advanced features, plus cybersecurity concerns that didn’t exist in the electromechanical era.

Now, testing involves:

Secure configuration management to prevent unauthorised changes

Network segmentation verification for IEC 61850 communications

Firmware validation to ensure devices haven’t been compromised

Access logging for compliance with NERC CIP requirements

These critical system integrity requirements add time and complexity to every test procedure.

Reporting and compliance expectations have grown

Utility reporting requirements have evolved. It’s no longer enough to say “test passed.” Teams need structured evidence, digital audit trails and repeatable workflows.

Instead of a simple pass/fail sheet, modern compliance frameworks demand comprehensive test records, including:

Pre-test system configuration snapshots

Step-by-step procedure documentation with timestamps

As-found versus as-left settings comparisons

Detailed fault simulation results with waveform captures

Post-test functional verification records

If your current process relies on screenshots and manual notes, you’re already at a disadvantage. You need tools that build reports as you go – no added effort (more on that shortly).

The ageing workforce problem

Many utilities are losing their most experienced protection engineers to retirement just as systems are becoming more complex, creating a knowledge gap where:

Younger engineers inherit complex systems without the organisational knowledge of why specific settings were chosen

Experienced engineers are overwhelmed trying to mentor while handling increased workloads

Contractor support becomes essential but inconsistent in quality and availability

The energy sector skills shortage means that testing procedures must be more foolproof and self-documenting than ever before.

Engineers are burned out by complicated software

A recurring frustration we hear from engineers:

“The software can probably do it, but nobody on my team has time to learn it.”

The job doesn’t need more powerful platforms. It needs useful ones:

Interfaces that make sense in the field

Test templates you don’t need to program from scratch

Systems that let you work manually or automatically, depending on what the job needs

The training paradox is that many utilities invest in sophisticated testing platforms but can’t afford the time to train teams properly.

Engineers end up using only 20% of the software’s capabilities, often reverting to manual methods that defeat the purpose of the investment.

Common software pain points:

Over-engineered interfaces requiring multiple clicks for simple tasks

Rigid test sequences that don’t match real-world troubleshooting needs

Poor offline capability that leaves engineers stranded in remote locations

Incompatible file formats between different manufacturers’ systems

Limited customisation without programming knowledge

The hidden costs of current approaches

Most organisations don’t realise how much these challenges are costing them:

Time multiplication

A test that once took 30 minutes now routinely takes two hours, factoring in:

Setup complexity for mixed IED environments

Documentation requirements

Troubleshooting non-standard configurations

Coordination with multiple teams (IT, Operations, Compliance)

Error amplification

Manual processes under time pressure lead to:

Incorrect settings being left in place

Incomplete test coverage

Documentation errors that surface during audits

Repeat visits to correct oversights

Resource inefficiency

Engineers spend increasing time on administrative tasks rather than actual testing and analysis.

So what can you do?

We’re not here to pitch a total digital overhaul. You’re busy.

What you need are modular upgrades that help you get the job done – faster and with fewer errors.

The practical path forward

Start with standardisation: before investing in new tools, standardise your current processes. Create templates for common test scenarios that work regardless of the software platform.

Think beyond your current setup: Choose tools that integrate smoothly with your existing equipment and processes — but also compare solutions to ensure you get the best fit for your workflow and keeps you from being tied to a single process.

Prioritise offline capability: remote substations and communication issues are facts of life. Any testing solution needs to work reliably without constant network connectivity.

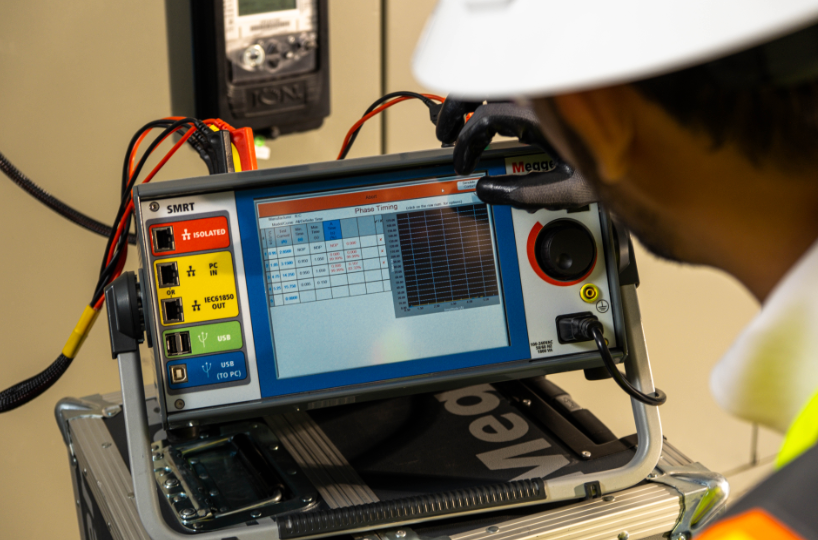

That’s where systems like SMRT and FREJA with RTMS software come in:

Over 400 ready-to-use test templates

Manual and automated workflows in one interface

Built-in reporting – no bolt-on tools

Works offline – ideal for substations with limited connectivity

You don’t have to change everything. You just need a tool that fits into how you already work – and helps you do it better.

Building test capabilities across legacy, DER and digital relays

Modular approach: implement improvements incrementally rather than attempting wholesale changes. Start with your most time-consuming test scenarios and work outward.

Cross-training investment: develop multiple engineers who can handle complex testing scenarios. This reduces single points of failure and improves scheduling flexibility.

Vendor relationship management: establish strong relationships with testing equipment suppliers who understand utility constraints and provide ongoing support rather than just equipment sales.

Want to see where you stand?

If you’re concerned that your current setup is holding you back, we’ve got a quick resource for you to help you:

Identify common friction points

Benchmark your workflow

Decide what to fix first

What’s next?

You don’t have to tackle everything at once. Small, targeted improvements in your testing workflow can deliver significant time savings and reduce stress for your entire team.