As for many manufacturing sectors, sustainability continues to be high on the priority list in the lighting industry. With new regulations and customer demands, it’s only going to become more important. But with so many sustainability standards out there, how do you know which matter most for your business?

Max Robson, Environmental Metrics and Training Manager at Recolight, outlines the environmental metrics for lighting.

The future of lighting is clear: highly efficient lighting made from sustainable or recycled materials, in factories that use renewable energy, and powered by a decarbonised grid, must be a priority.

Some lighting companies are already leading the way, while others are just getting started. But how do they prove the steps they’ve taken? And how do specifiers and buyers separate the truly low-impact products from those simply claiming to be “sustainable”?

That’s where sustainability metrics come in. Over the last few years, various frameworks have emerged to measure and certify environmental impact. But with so many options, where should businesses focus their efforts (and budgets)?

TM66: Rating the Circularity of Economy Lighting Products

TM66 is a tool that helps lighting manufacturers assess how well their products align with circular economy principles. Created by the Society of Light and Lighting (SLL), it gives products a score from 0 to 4, showing how well they contribute to a circular economy.

The Good

-

Quick and cost-effective way to evaluate products.

-

Encourages manufacturers to design with manufacturability in mind.

The Limitations

-

Mainly used in the UK.

-

Can be self-certified, reducing credibility.

-

A single score can oversimplify the true environmental impact of a product.

Overall, TM66 is a great starting point, but it’s not the full picture. It gets the conversation going, but it won’t be enough for detailed sustainability assessments.

TM65: Calculating Embodied Carbon in Lighting

TM65 helps manufacturers estimate the embodied carbon of their products – the carbon emissions generated from raw materials, manufacturing, transport and end-of-life treatment. As the UK grid becomes greener, the operational footprint will decrease and embodied carbon will play a bigger role in the overall environmental impact of lighting products.

The Good

-

Simple calculation which uses representative conversion factors to generate a CO2 footprint

-

Provides a simple way to compare products based on embodied carbon.

-

Based on real product component materials and masses.

The Limitations

-

Mostly relevant to the UK market.

-

Can be self-certified.

-

Focuses only on embodied carbon, leaving out other environmental factors.

-

Is a high-level methodology which only reasonably approximates the embodied carbon.

If a company wants to start measuring its product’s environmental impact, TM65 is a great first step. But as sustainability expectations grow, businesses will need to use a more accurate methodology and to go beyond just embodied carbon.

Life Cycle Assessment (LCA): A Full Picture of Environmental Impact

A Life Cycle Assessment (LCA) is a more detailed analysis of a product’s total environmental impact, from raw materials to disposal. Unlike TM65, which focuses on embodied carbon, an LCA considers the whole footprint of a product. It is also used to calculated multiple impact categories, such as water use, pollution, resource depletion, and more.

Because LCA studies rely on real-world and evidence-based data, they’re considered the most thorough way to measure a product’s environmental footprint. For companies looking to take sustainability seriously, an LCA is the most powerful tool to use at the product level.

Environmental Product Declarations (EPDs): The Verified Approach

An Environmental Product Declaration (EPD) is a verified document that presents the results of an LCA in an internationally recognised and standardised way. EPDs are already widely used across many industries and are expected to become more common in lighting, especially as EU regulations evolve.

EPDs are third party verified to ensure that they follow the right standards. This is designed to allow reasonable comparison between products. With the UK potentially aligning more closely with EU sustainability rules, EPDs could soon become a legal requirement in the construction sector.

Where is the Industry Headed?

TM66 and TM65 have been instrumental in pushing the industry toward sustainability and have catalysed the understanding and adoption of life-cycle thinking in product design.

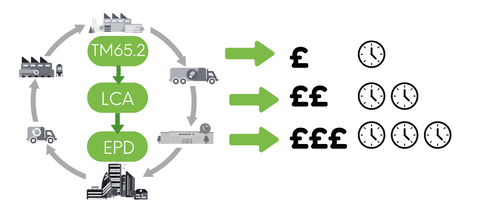

TM66 and TM65 gained traction based on their affordability and simple implementation. LCAs and EPDs require more investment but can return far more granular results which will supersede any TM65 at the point of specification. Thankfully, new automated platforms like One Click LCA are making the process more accessible.

This said, cost-effective solutions are still needed for smaller manufacturers, but one thing is certain: sustainability isn’t going anywhere. Customers, contractors and wholesalers who stay informed and work with environmentally responsible suppliers will be playing a key role in building a greener future.

Recolight’s LCA and EPD Service

Recolight offers a comprehensive Life Cycle Assessment (LCA) and Environmental Product Declaration (EPD) service to help lighting producers calculate and communicate the environmental impact of their products.

The service includes LCA and EPD workshops, providing in-depth training on LCAs, obtaining EPDs, and understanding their role in sustainable product design. The workshop is ideal for manufacturers looking to enhance their sustainability credentials and meet evolving regulatory requirements.

As an extra stepping-stone into EPDs, Recolight offer a One-Off service whereby our experts will use manufacturing data to produce, verify and publish an EPD for £7,000.

Finally, Recolight also provide ongoing support to manufacturers looking for an in-house solution, by providing additional training on the use of the One Click LCA software.