This article covers a number of recent discussion topics with customers, relating to testing different Types of RCD. Our original article dated October 2019 goes into more detail on background subjects.

https://www.voltimum.co.uk/articles/rcd-testing-18th-edition-basics

Why does BS 7671 18th Edition only refer to testing Type AC RCDs ?

At the present time the recommendations from the IET are Quote: ”.. Type A, B and F RCDs are tested in the same way as an AC RCD. Details of the test procedure and maximum disconnection times can be found in IET Guidance Note 3. “

See https://electrical.theiet.org/wiring-matters/years/2019/77-september-2019/which-rcd-type/

The maximum disconnection times in Chapter 4, Appendix 3 Table 3A and the requirements of Chapter 6 relate to AC fault currents (residual currents). The IET minimum testing recommendations to meet Regulation 643.7 and 643.8 are based on Type AC Test Currents, irrespective of the Type of RCD.

Why is this ?

All RCDs including Type A, F and B must be able to detect Type AC fault currents – refer to tripping requirements in clause 531.3.3

The AC tests verify that the RCD mechanism / tripping characteristic is functional, that it is not faulty /damaged in any way following transport and installation – This is required by the standards as RCDs provide additional protection in the event of a failure of the basic protection method – see Chapter 41.

How would a person be exposed to different “Types” of shock current ?

In this example Fig 1 (washing machine), with the appliance switched off, the shock hazard due to an insulation fault related to the supply cable or carelessness when connecting the equipment would be from the 50 Hz AC supply.

Referring back to Fig 1, if the appliance is running with an insulation fault on the supply cable, a person would be exposed to a shock current containing the fundamental frequency 50Hz + any additional frequency components generated by the washing machine inverter + the motor. For more details on Type F RCDs -see https://www.voltimum.co.uk/articles/18th-edition-type-f-rcd-deep-dive

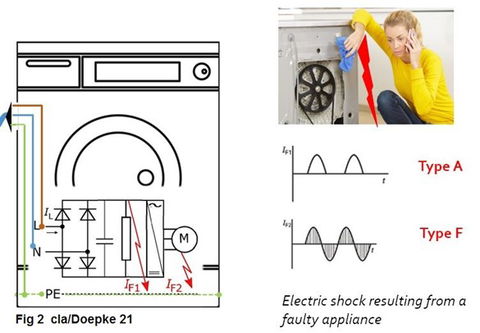

Referring to Fig 2, an insulation fault (IF1) between the output of a single phase bridge rectifier to the appliance casing results in a pulsed fault current. With a frequency of 50 Hz, this would be classified as a Type A residual current. A person touching the casing would be exposed to this fault current if the circuit upstream did not contain a suitable RCD for detecting Type A residual currents.

An insulation fault (IF2) located between the output of the inverter to the casing, produces a fault current with various frequency components related to the inverter switching frequency and the motor speed – classic Type F residual current.

In summary, the current flowing through the body will be determined by the characteristics of the appliance, the operational status, the location of the fault (producing the hazard) and the point where the person comes into contact with the faulty appliance or conductor. The Type of RCD mounted upstream will determine if the person is protected against the various shock hazards associated with the appliances connected to the circuit.

Do I need to complete other tests on the RCD if it is a different Type ?

BS 7671 gives recommendations on minimum requirements and at the moment, additional tests relating to Type A, F or B RCDs are classed as Manufacturing Type Tests by the IET Quote:

”.. There are no additional requirements for the installer to check for correct operation whilst subjected to DC residual current. This testing is carried out during the manufacturing process and is called type testing, which is no different from the way we currently rely on circuit-breakers under fault conditions.”

See https://electrical.theiet.org/wiring-matters/years/2019/77-september-2019/which-rcd-type/

BS7671 covers the basic electrical requirements, which the HSE state “as likely to achieve conformity with the relevant parts of the Electricity at Work Regulations 1989” See Page 13.

Personal Judgement – Ref BS7671 Page 2

The Person responsible for Testing / Signing-off the Installation Test Certificate / Condition Report, has to make a judgement on what is appropriate for the installation and the associated risks. There may be contractual requirements associated with a job - for example the final customer has requested specific tests to be completed following a site review. There may be additional risks associated with the installation e.g. special locations, EV Charging, Medical Locations, Exhibition Grounds …

Why am I completing this particular RCD Test ?

If we are not familiar with the characteristics of the product we trying to test or understand what the test instrument is actually doing during its’s test cycle, we cannot logically interpret the results.

Going through the motions of testing without understanding the reasons why we are completing a particular test may not make the installation any safer.

For example Functional tests – Regulation 643.10: To verify that a Type A RCD will operate correctly under normal service conditions e.g. unwanted tripping due to an accumulation of AC leakage currents (see 531.3.2). This is checked by completing the 50% test with an AC test setting- Not an A test setting!!

Why use an AC test setting for this particular test example?

Because leakage current flows during normal operation with no faults present in the circuit i.e. it is an AC waveform. Therefore we use the AC test setting to verify the sensitivity of the Type A RCD to unwanted tripping, associated with an AC waveform. Referring back to Fig 2 we can see that a Type A residual current only flows under fault conditions, therefore a Type A test setting* has no relevance to this particular test.

This is just one example to illustrate the importance of understanding the reasons for specific tests, the characteristics of the products we are testing and also what the Test Instrument is doing when it is set to a particular function.

*The standard value of residual non-operating current 0.5 I ∆n is only relevant on Type AC current. This value is not relevant to Type A pulsed residual currents, where values of non-operating current depend on the starting instant α - see RCD tripping thresholds rcd-testing-18th-edition-basics

Summary

A basic set of RCD tests may be suitable for some installations. Complex or high risk installations may require additional tests based on the requirements of the customer. This would need to be supported by the appropriate knowledge of the installation and location requirements. Familiarity with the characteristics of the specific protection devices installed and investment in training and practice, with the associated test instruments helps make effective and efficient use of time on site. The IET resources web site gives access to a wide range of additional books and guidance for special locations. These publications contain additional information on RCD requirements, supporting the Wiring Regulations.

For further information on different Types of RCD, go to http://www.doepke.co.uk/ or email [email protected] if you have a specific question relating to RCDs / applications.

C.Andrews

Technical Manager - Doepke UK Ltd