In today’s increasingly complex electrical installations, having a reliable and flexible wiring solution is critical. WAGO’s TOPJOB®S multilevel installation terminal blocks offer the perfect answer for those looking to save space, time, and energy in their electrical work. These terminal blocks are ideal for industrial, commercial, and building installations, offering versatility and ease of use. Below are some key practical tips to ensure you get the most out of WAGO’s system.

1. Optimize Space on the DIN Rail

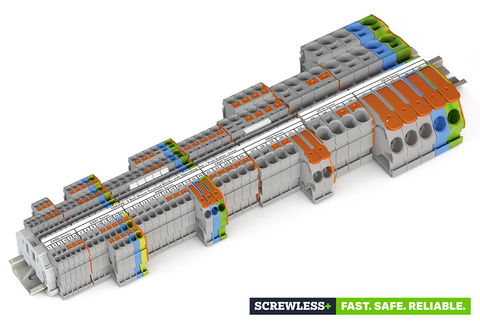

One of the standout features of TOPJOB®S multilevel terminal blocks is their ability to accommodate multiple levels of connections in a single block. This space-saving design is handy when working with dense control cabinets or panels with limited room. Installers can maximize space efficiency by stacking connections vertically while still adhering to DIN standards. Be sure to evaluate your layout before installation to plan the most effective use of space.

2. Tool-Free Installation with Push-in Cage Clamp® Technology

Speed and reliability are essential in any installation, and WAGO’s push-in Cage Clamp® technology simplifies the process. This system allows solid conductors to be inserted directly without needing tools. For stranded conductors, you can use a simple screwdriver to insert them just as securely. This not only speeds up the installation process but also ensures a strong, vibration-proof connection. The tool-free design minimizes the risk of errors while saving time, especially when working under tight deadlines.

3. Leveraging Flexible Connection Options

The multilevel nature of these terminal blocks supports flexible wiring configurations. Whether you’re working with solid or stranded conductors, TOPJOB®S blocks accommodate a wide range of wire types and sizes. This flexibility is crucial in industrial settings, where different components may require varied wiring solutions. Be mindful of the rated current and voltage limits for each terminal block level to avoid potential overloads.

4. Comprehensive Marking System for Clear Connections

When dealing with multilevel terminal blocks, clearly identifying each connection is vital for future maintenance and troubleshooting. WAGO offers a range of marking options, from pre-printed labels to custom markers, helping installers maintain clarity even in the most complex installations. A well-labelled system can save significant time during repairs or upgrades, so it’s worth investing in proper marking from the start.

5. Testing and Maintenance Made Easy

Testing your connections is a critical step in ensuring safety and functionality, and WAGO’s TOPJOB®S terminal blocks make this process straightforward. These terminal blocks feature dedicated test points, allowing for easy measurement without having to disturb the wiring. Routine checks can be performed quickly, reducing downtime and making it easier to identify any issues before they lead to system failures.

6. Access to a Range of Accessories

WAGO offers a variety of accessories designed to complement their terminal blocks. From end and intermediate plates to jumper bars, these accessories further enhance the flexibility and functionality of the installation. For instance, jumper bars can be used to easily connect multiple terminal blocks, streamlining wiring for common potentials. Keep a set of essential accessories on hand to make adjustments and modifications more efficient.

7. Long-Term Durability and Reliability

The robust design of TOPJOB®S terminal blocks ensures that they perform well even under harsh conditions. Their vibration-resistant connections and corrosion-resistant materials contribute to the longevity of the installation. This reliability makes them an ideal choice for demanding environments, such as industrial plants and automated systems. By choosing high-quality components like these, you reduce the need for frequent replacements, saving both time and cost in the long run.

8. Compliance with Global Standards

WAGO’s TOPJOB®S terminal blocks comply with international safety and performance standards, making them suitable for use in a variety of applications across the globe. Whether your project requires compliance with UL, IEC, or EN standards, you can trust these terminal blocks to meet the requirements. Always verify the specific regulations applicable to your installation, especially in critical industries such as energy, transportation, or manufacturing.

Conclusion: Simplify Your Installations

WAGO’s TOPJOB®S multilevel installation terminal blocks are designed to simplify even the most complex electrical installations. From tool-free wiring and space-saving designs to comprehensive marking and testing systems, these terminal blocks offer the flexibility and reliability that modern electrical systems demand. By following these practical tips, you’ll ensure that your installation is efficient, safe, and built to last.

For more detailed information and application-specific guidance, visit https://www.wago.com/gb/electrical-interconnections/discover-rail-mount-terminal-blocks