This article reviews the general health and safety guidance for assessing and controlling such risks contained in the HSE Guidance Note GS6 (Fourth edition) Avoiding danger from overhead power lines (2013).

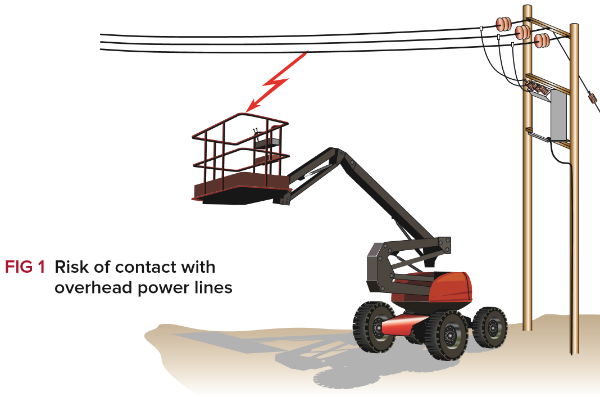

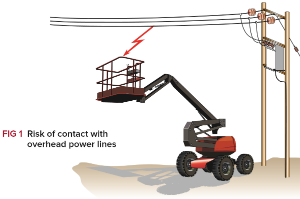

Overhead electricity lines are placed at specified heights above the ground so that the risk of accidental contact with persons, plant or equipment is minimised. Despite this, construction workers continue to suffer injuries as a result of contact with overhead power lines.

While the ideal safety option is that the network operator removes the risk by isolating the relevant section(s) of the overhead line prior to the work being undertaken, in most cases this is not a practical option. Therefore, where work, including temporary or short duration work, is intended to be carried out within a distance of 10 m from an overhead line the risks should be managed.

Work near power lines should generally be restricted to daylight hours of good visibility, and a site-specific risk assessment should take into account the voltage rating and height of the line and the following:

The position and proximity of the work activity – including whether access is required underneath the line

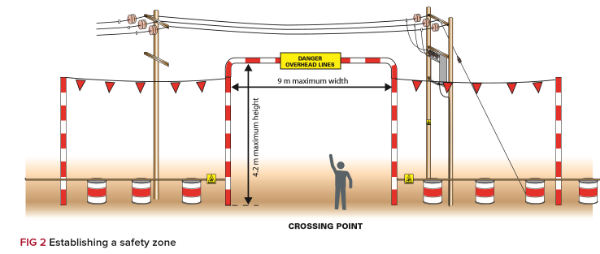

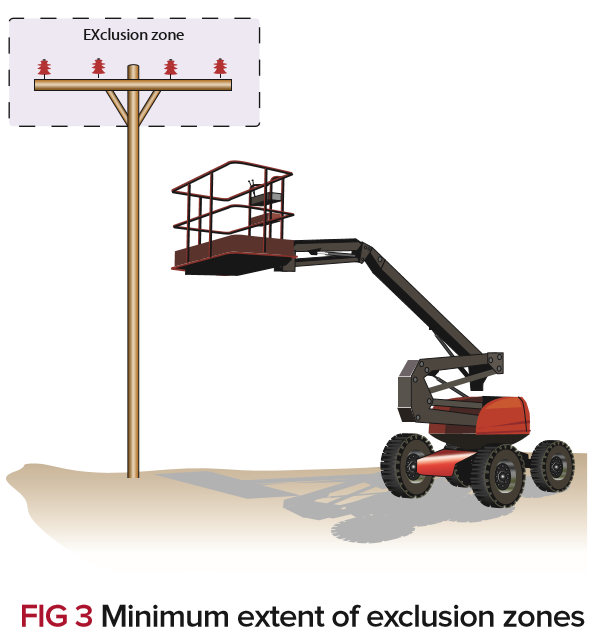

Where construction work is intended to be carried out within ten metres of an overhead electricity line then it may be necessary to establish a safety zone to separate the work site from the vicinity of the overhead line. Generally, this is achieved by using ground-level barriers, such as large steel drums filled with rubble or concrete, as shown in Fig 2. Alternatively, wire fencing earthed at either end, or banks of earth with posts inserted, may be used.

The safety zone should extend 6 m horizontally from the nearest conductor on the relevant side of the line, running parallel to the position of the line. Where both sides of the line are accessible then a safety zone should be established on each side.

Where movement of machinery or equipment is planned to take place underneath the overhead line a crossing point (high visibility passageway) should be erected using fences and height restriction goalposts of non-conducting materials, such as timber or plastics, to define the route (Fig 2 refers).

Each crossing should be assigned a unique number and, to alert drivers and plant operators of the hazard before crossing, warning signs should be placed on all approaches. The height of the goalpost (the crossbar) should not exceed 4.2 m and the width should be kept as narrow as possible and should not exceed 9 m. Where the width cannot be spanned by goalposts then plastic ropes or steel wire, earthed at either end, may be used with flags or bunting attached.

Safe clearance distances

Safe clearance distances

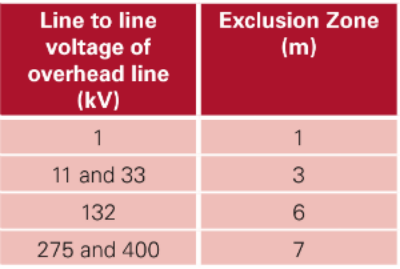

Where work encroaches on or has to be carried out within the safety zone, the risk assessment should verify that the safe clearance distances of the specified exclusion zone will not be breached. An exclusion zone is the minimum space, based on the voltage rating of the overhead line, that should be maintained in all directions around the line conductors so as to prevent electrical arcing and flashover.

Measures to ensure safe systems of working may include installing barriers to make sure a safe distance is maintained or restricting access to only vehicles, plant and equipment, including ladders that cannot breach the exclusion zone where they are at their maximum operating reach, or requiring all such access vehicles to be fitted with height restrictors.

In addition, storage areas for metallic equipment such as scaffold poles, ladders or lengths of conduit or trunking should be positioned at a safe distance from the exclusion zone.

In addition, storage areas for metallic equipment such as scaffold poles, ladders or lengths of conduit or trunking should be positioned at a safe distance from the exclusion zone.

The Energy Networks Association (ENA), Technical Specification 43-8 - overhead line clearances provides details are on safe clearance distances.

The competence, supervision and training of those working in the area

All those involved in work near overhead lines should be aware of the risks and recognise their responsibilities for maintaining safe systems of work, in particular:

• adhering to safe working procedures such as permit to work systems.

• ensuring plant and access vehicles such as mobile elevating work platforms (MEWPs) are only operated by trained persons in accordance with the particular safety operating instructions.

• reporting damaged or missing safety equipment such as warning signs, barriers, and goalposts immediately.

GS6 may be downloaded free of charge from http://www.hse.gov.uk/pubns/gs6.htm

For information about the NICEIC Approved Contractor or Domestic Installers schemes, visit www.niceic.com or call 0870 013 0382