Published: 23 March 2015

Category: Technical articles

In any low voltage (LV) electrical installation, correctly designed back-up protection and discrimination will minimise disruption caused by electrical faults. To achieve this, proper electrical protection studies may be necessary, as James Hunt shows:

Circuit protection devices, such as fuses, miniature circuit breakers (MCBs), moulded case circuit breakers (MCCBs) and air circuit breakers (ACBs), are required to protect cables, electrical devices, components and circuits from over-currents and short-circuits. Such devices also greatly reduce the risk of fire occurring.

Choosing the right ones for relatively simple installations is well within the capabilities of competent electrical contractors. For larger, more complex systems, however, where it is essential to provide correct discrimination and coordination of components, an electrical protection study may be required.

An LV electrical installation in larger buildings, such as office blocks, typically has a main switchboard fed by a HV/LV transformer and protected by an ACB. This feeds out-going MCCBs, which then feed smaller fuse, MCB or MCCB-protected distribution panels. Circuit protection device selection depends on the normal operating current and possible fault currents, which must be determined.

Other factors to consider include selecting the correct product standards, such as the harmonised industrial circuit breaker standard, BS EN 60947-2, rather than BS EN 60898 domestic circuit breaker standards for MCBs.

Whatever device is chosen, it is not enough to ensure that it works correctly if a fault occurs; it is also essential that it does not trip unnecessarily.

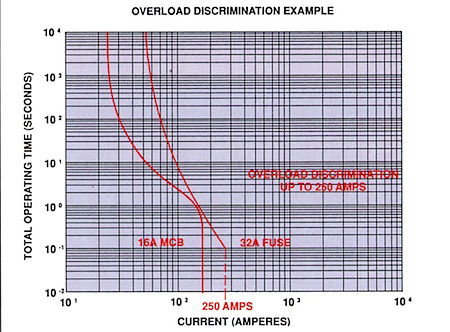

Proper discrimination is essential. Discrimination (or ‘selectivity’) should ensure that only the protection device immediately upstream of a fault trips, so that the rest of the system is unaffected. In an incorrectly designed installation, the protection devices in a chain may all blow/trip simultaneously if a short circuit occurs. This is a nuisance and a danger; for example, lights going out at night when there are people in a building could cause accidents.

Striking the balance between maintaining maximum protection for minimum disruption is not always easy, but specifying circuit protection devices having adjustable tripping characteristics is one way in which the discrimination can be achieved to minimise any disruption caused by a fault.

Electrical protection studies

To achieve discrimination in domestic and other simpler installations is relatively easy for electrical contractors using discrimination tables published by LV equipment manufacturers including ABB, Eaton, Schneider Electric and Siemens. However, for larger commercial and industrial LV systems, this can become more complex, and an electrical protection study may be necessary.

Electrical protection studies involve analysis of discrimination, the protection coordination of various electrical components, and cable protection. Protection coordination needs a good understanding of phase and earth short circuit currents present in a scheme, detection, and safe clearing of the faulted equipment. Such studies are necessary to minimise the extent and duration of any service interruption, and should also minimise damage to system components.

Traditionally, electrical designers have carried out such studies, but some have been passing the buck to electrical contractors and in turn, device manufacturers. This is rather unfair. In many electrical installations, there may be specific protection issues, as well as cumulative overload considerations.

An example of the latter is motor-driven ventilation fans, which produce high inrush currents at start-up. Even though components may appear to have been correctly selected at first sight, if several such fans start simultaneously, the resulting overload can cause a trip, yet it may manifest itself on site as an intermittent problem that is very difficult to find. This is just one easy trap that a protection engineer, who is not directly involved in the design, can fall into.

For reasons such as this, electrical designers should really carry out such work, as used to be the case, because they are the ones who understand what is required of the installation from the end client’s perspective.

Electrical protection studies may be even more necessary today, even for older upgraded electrical installations. This is because electricity demand is increasing, so protective devices that were originally correctly selected may become inadequate. The study should calculate the likely minimum/maximum prospective fault currents at every supply chain node. From this, the choice of all protective devices (and their settings where necessary) can be determined.

Another aspect to consider includes hazards resulting from an arcing fault occurring with a timed trip setting. This is important for equipment used in hazardous areas, as explosion protection properties can be easily compromised by arc faults.

Therefore, the study may also need to examine how a trip setting is selected for the detection of arcing faults, what safety factor to apply, and the electrical protection design in terms of discrimination, speed, redundancy levels, sensitivity and stability.

This is not the end of the story, as very fast acting circuit protection devices, such as cartridge fuses, can limit the short circuit fault current because they trip before the current has peaked. This can greatly reduce magnetic and thermal stresses, minimising damage to circuit components; an integrated system protected by fuses may ideal.

So whether to use a fuse or a circuit breaker should also be tackled by an electrical protection study – both have their own advantages. Moreover, high fault currents may affect the next protective device in the chain, so it is important to understand how combinations of devices will behave.

Even so, full discrimination may not always be possible, because if the distribution circuit and device characteristics are such that any fault current would be of long duration or too high, long-term damage could still occur.

Installation audits

Related to electrical protection studies are complementary consultancy solutions, including audits, to monitor and protect electrical distribution networks and equipment. Schneider Electric, for example, provides such complementary consultancy solutions, which help identify potential problems and manage risk.

Careful monitoring can reduce downtime and extend equipment life by protecting against spurious tripping, unnecessary outages, power and lighting failure and overheating of conductors, motors and starters.

And finally…

Competent electrical contractors can determine most discrimination requirements for many electrical installations, using manufacturers’ time/current characteristics and tables of pre-arcing and total let-through energy for fuses and discrimination tables for circuit breakers.

Even so, where larger, more complex systems are concerned, it is often better that discrimination and coordination studies are carried out by experts through an electrical protection study. Such experts should be experienced in optimising electrical systems to reduce chance of disruption caused by a fault, while minimising risk of damage.