Providing contractors with valuable information to help them keep up to date, Click Scolmore looks at considerations to bear in mind for the selection and erection of electrical accessories in those locations that are subject to mechanical impact.

Any electrical equipment must be both fit for use (133.1.1), suitable for the location in which it is to be installed (132.5.1), and installed in accordance with the manufacturer’s instructions (134.1.1) and erected such that it is not compromised (134.1.2).

IK codes

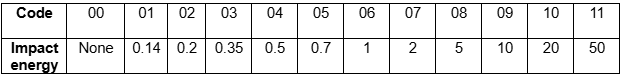

BS EN 62262: 2002+A1:2021 Degrees of protection provided by enclosures for electrical equipment against external mechanical impacts (IK code), is a standard which ‘…refers to the classification of the degrees of protection provided by enclosures against external mechanical impacts…’.

Table 1 in this standard detail the following codes for the impact energy (in joules) the equipment is capable of withstanding.

Fig 1 IK codes illustrative

All references are to BS 7671 unless otherwise stated.

Whilst Appendix 5 of BS 7671 does not reference IK codes, rather it references ‘low’, ‘medium’ and ‘high’ severity of impact, there are a number of regulations within the standard which make specific references to BS EN 62262, including for example, Regulation 708.512.2.1.3, 709.512.2.1.4, and 712.512.

Design considerations

When designing an installation, it is important that the designer gives careful thought to the nature of the activity and conditions likely to be found in the installation.

Where there is a likelihood of a risk of impact designers, amongst other things, should select products capable of withstanding such impact. Whilst there only a few regulations detailing specific parts of an installation requiring a minimum energy withstand (IK code), there is a more general need to ensure that any installed equipment is suitable.

Installation

There is a duty on installers to ensure that they install any equipment in accordance with the guidance issued by the manufacturers of a product. More than this however, they should also ensure that their activities do not compromise the product itself. For example, this might be caused by excessive force, incorrect location, poor fixing and the like.

Examples

Consider the following cases.

A campsite has supplies available for various tent plots. Regulation 708.512.2.1.3 is very clear, and because of the increased risks associated with persons being in contact with Earth, installed equipment must have a minimum resistance to impact of IK08 (5 J).

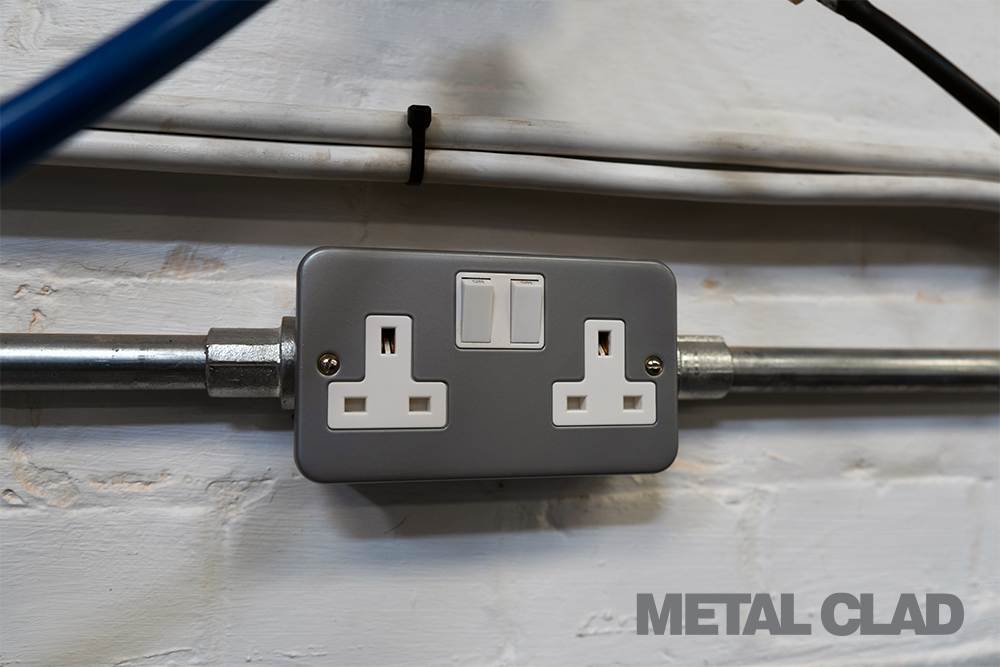

A small industrial unit has a series of wall-mounted, surface wired accessories. In this instance there is no minimum declared IK value however the general principles apply; that is to take account of the environmental conditions which apply. In this instance, therefore, a designer would likely select metallic outlets.

Conclusion

It is important that both designers and installers take due account of the likelihood of impact when selecting and installing suitable products for those installations which have a harsher environment. Additionally, certain special locations detail specific minimum impact requirements.

Metal Clad – tough and durable wiring accessories

Scolmore’s comprehensive Metal Clad range is offered as part of Click’s Essentials wiring accessories and features electrophoretically coated plates and back boxes that provide a durable and long-lasting heavy-duty finish.

The growing Metal Clad range includes a number of 2 way switch plates, switched sockets, safety shutter switched sockets and fused connection units, as well as 1-gang and 2-gang switched sockets with Outboard Neon Rockers. Some recent additions also feature a 13A 2 Gang DP 3 Pin Safety Shutter Switched Socket Outlet with Outboard Rockers (Twin Earth).

All switch products are of modular construction allowing the installer total freedom in designing customised switching solutions according to on-site needs. Unfurnished plates and mounting boxes are available for use in conjunction with Click’s extensive range of MiniGrid and New Media modules.

All Metal Clad socket outlets and spurs are tested and approved to BS1363.