In almost every installation, contractors can save time and money, as well as providing their customers with increased flexibility, by choosing busbar trunking over cable, says Schneider Electric's Lynsey Perks. She analyses in detail the benefits of busbar trunking, and provides contractors with useful guidance on its use:

Even then, it was a useful alternative to cable, particularly for high current applications where the relatively unsophisticated insulating materials of the era meant that the cables would be bulky, difficult to handle, and susceptible to damage if used in adverse environmental conditions. In truth, however, those early incarnations of busbar trunking offered only a few of the benefits provided by today's products.

The easiest way to understand these benefits is to start by looking at the limitations of cable. It's worth noting that, because cable is so familiar, it's easy to be blind to many of these.

First and foremost, cable-based installations are inflexible. Changes can be made, but even a job as simple as relocating a few lighting fittings to accommodate alterations in an office layout is inconvenient and costly.

Major changes and extensions to existing installations can be very disruptive, particularly as the electrical supply to large parts of the system will almost certainly have to be turned off while the work is being carried out. These considerations are increasingly important, as the dynamic nature of business today leads to the need for frequent premises restructuring.

Another negative aspect of traditional building distribution systems that often passes unnoticed is that they are time consuming to install. First the cable trays, conduit or trunking have to be fixed in place, followed by the cable itself. Every single connection has to be made by hand.

The time needed for these processes quickly adds up, and often has a significant impact on the cost of a building project, as well as the time to completion. Once again, these are important concerns for modern businesses where both time and money are scarce resources.

Though many other limitations could be easily identified for cable it is, perhaps, now more profitable to turn to the positive benefits provided by modern busbar trunking.

Essentially, like its earliest predecessors, this usually comprises insulated solid copper or aluminium busbars encased in steel. The key difference is that modern systems have been designed from the outset for installation applications, rather than being simply adaptations of switchboard busbar assembly.

Modular, with ease of connection:

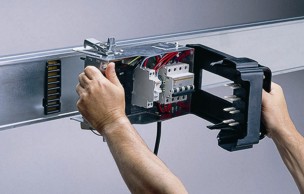

Modern busbar trunking is invariably modular, and is supplied in pre-fabricated lengths, as part of a product range which includes corner pieces, T-connectors and other accessories that make it easy to configure for virtually any application - see picture 1.

In most systems, the trunking components simply plug into one another. This makes installation fast and easy, especially when it is remembered that no cable trays are needed. Except for a few flexible products, busbar trunking is self-supporting.

One of the most important benefits of busbar trunking, however, is the way in which connections are made to it. At regular intervals along its length, the trunking has provision for fitting tap-off units. These are devices that plug into the trunking, and provide terminals for the connection of power outlets, luminaires or other electrical loads.

On the face of it, that doesn't sound too exciting, but the key feature is that tap-offs can be removed, added and repositioned as necessary. That makes the restructuring of electrical services simple and inexpensive, providing the level of flexibility which modern businesses rightly expect.

Indeed, there's a further bonus; with most busbar trunking systems, tap-offs can be removed and fitted without turning off the electrical supply. This means electrical equipment that is not directly affected by modifications can continue to be used while the changes are in progress.

Facilitates decentralisation:

Busbar trunking also facilitates the implementation of decentralised electrical distribution systems. Cabled installations are almost always designed around a central distribution panel, which contains all of the circuit breakers and other protective devices. Typically, several circuits will be fed from a single protective device, which means that, if a fault occurs on one of these circuits, power will be lost to all of them.

With a decentralised installation using busbar trunking, the protection is combined with the tap-off units, and is, therefore, close to the equipment it is supplying. This makes it easy for each piece of equipment to have its own protective device, which greatly reduces the impact of faults. A further benefit is that local protective devices simplify fault finding and maintenance - see picture 2.

Clearly, except perhaps in small installations where the likelihood of future changes is remote, busbar trunking has a lot more to offer than cable. Why, therefore, is it not universally used?

As might be imagined, busbar suppliers have devoted considerable effort to answering that question, and have found that two reasons are usually given. The first is cost, the second is that it is generally believed to be more difficult to design an installation with trunking than with cable. Let's look at these points. It is certainly true that, as far as the basic materials are concerned, busbar trunking is likely to cost more than cable. But this is far from being a complete analysis of the situation.

As we have seen, trunking is much quicker to install than cable. The resulting savings in labour costs are almost always enough to tip the balance in favour of trunking. For example, a detailed comparison recently carried out which compared busbar trunking and conventional cable in a simple lighting installation showed that overall costs were reduced by almost 30%.

Even this, however, isn't the end of the story. For building owners, earlier completion of electrical work potentially means that they can occupy or rent out the building sooner, which translates into further financial benefits. For contractors, faster installation means that staff are freed up to move on to the next revenue-generating project. Moreover, these are only the initial cost benefits which can be expected when installing a system. When lifetime costs are considered, the financial outlook becomes even more attractive.

Steel-cased busbar trunking is far less susceptible to damage than cable in cable trays, so it would be valid to argue that maintenance costs are reduced, along with the risk of damage caused by electrical faults. The really big savings accrue, however, when modifications and extensions are needed to the installation. Again, as we've already seen, with busbar trunking these are quick and straightforward, whereas with cable they're disruptive and costly.

Now let's turn to technical considerations. For every electrical contractor designing cable-based installations is a very familiar process and it is, therefore, seen as quick and easy. In fact, the process of selecting and sizing busbar trunking is even quicker and easier, but for first-time users, it is, of course, less familiar.

The basic design criteria for busbar trunking are exactly the same as those for cable. Namely, the current rating (Ith) of the trunking must be greater than that of the protective device which, in turn, must be greater than the maximum load current. When it comes to the more detailed aspects of design, however, busbar trunking begins to score over cable.

One important benefit is that the current rating of busbar trunking is far less affected by grouping factors and ambient temperature than that of cable. In fact, since busbar trunking is a modular product with the conductors already installed, grouping factors need not be considered at all. This means that one time-consuming step is completely eliminated from the design process.

When it comes to temperature derating, busbar trunking is clearly superior to cable. Even at modest ambient temperatures trunking typically needs to be derated 10% less than an equivalent cable, and at an ambient temperature of 50°C, this difference can rise to 30%.

For both cable and trunking, voltage drop must, of course, be considered. Again, however, trunking almost always outperforms cable. For currents between 1A and 100A, for example, it's not unusual for the trunking voltage drop to be around 50% lower than that of an equivalent cable. This simplifies the designer's work by allowing longer runs to be used, while remaining within the maximum allowable voltage drops laid down in the wiring regulations.

Not only are phase-to-neutral voltage drops lower than an equivalent cable-based installation, the earth loop impedance is also reduced. Lower loop impedance means that earth fault currents are higher, leading to faster disconnection times, irrespective of whether protection is provided by circuit breakers or fuses.

Reduced earth loop impedance also means that, in the event of a fault, exposed metalwork will rise to a lower voltage above earth, which, in turn, reduces the risk of serious electric shock.

Selecting protection devices is also an easy process, especially if the trunking is purchased from an organisation that also supplies the protective devices. In such an instance, detailed co-ordination data is almost certain to be available.

This is often provided in the form of easy-to-use look-up tables, and ensures that the device selected provides a suitable level of both overload and short-circuit protection. The availability of such tables removes the need to carry out calculations which compare energy let-through and withstand values for fault conditions, a process which is straightforward but nevertheless time consuming.

The use of tested and co-ordinated components not only reduces the amount of work necessary in designing an electrical installation, but also provides a valuable step toward achieving the best possible levels of safety.

Types of busbar trunking:

It is hoped that the foregoing has presented a convincing case for the superiority of busbar trunking, so let's conclude by looking at the types of products which are available. Essentially, a comprehensive range from a leading supplier might be expected to include products with ratings from 20A, principally designed for use in lighting installations, right up to 5,000A for use in the distribution systems of heavy industry.

Most of the products will use copper busbars in rigid steel enclosures but, at the low current end of the range, flexible products are becoming available. Ideal for use in lighting systems where the trunking is not required to support the weight of the luminaires, flexible busbar trunking is supplied on convenient reels, which can be handled just like conventional cable.

Also increasing in popularity, especially for use in rising mains, is trunking with aluminium conductors. This is lighter and easier to handle on site than conventional copper busbar trunking and, in many cases it can be installed by one person where two would previously have been needed. It also needs fewer mechanical fixings, making it even faster to install.

Naturally, measures must be taken to ensure that the contact between the aluminium bars and tap off outlets eliminates the risk of electro-galvanic problems at the joint. One approach which has proved particularly effective is for the manufacturer to equip the aluminium bars with bi-metal silver-copper laminate saddles at connection points and tap-off outlets - see picture 3.

Also worth mentioning, particularly in connection with risers, is the excellent fire performance offered by some types of busbar trunking. Where sandwich construction is used, there is no air space within the trunking, which means that it cannot convey hot combustion products in the way that ordinary wiring ducts invariably do. This makes meeting the fire safety requirements of the Building Regulations much easier with trunking than with cable.

Busbar trunking has a lot to offer, but it has to be accepted that some contractors who are more familiar with cable may still be a little reluctant to make such a radical departure from their usual practice when quoting for an important contract. They need have no fear - leading manufacturers back their products with comprehensive support, which embraces every stage of the project, from tendering, through design, to installation and commissioning.

With such a resource to call on, and given the undoubted cost and technical advantages of busbar trunking, what possible reason could there be for choosing the lesser option of cable?

Picture 1 shows modern busbar trunking with corner pieces, T-connectors and other accessories that make it easy to configure for virtually any application.

Picture 2 shows local protective devices that plug-in, so simplifying fault finding and maintenance.

Picture 2 shows aluminium busbars with bi-metal silver-copper laminate saddles at connection points and tap-off outlets.