Checks on the condition and suitability of test leads must be carried out prior to undertaking any tests.

Using test leads that are unfused, damaged, or not manufactured to a recognised British or Harmonised Standard may result in injury or death to the person carrying out the testing, due to electric shock, explosion and/or burns. Injury or death can result if the circuit under test is faulty, the insulation of the test lead or test probe is insufficient for the circuit voltage, or the person accidently short-circuits the test probes while in contact with live parts.

Solution:

As is the case for test instruments, it is essential that test leads are maintained in a safe and servicable condition. It is essential that testing methods do not create a danger to the tester or to other persons or livestock.

The reliability of test leads is essential in helping ensure the safety of the person carrying out the tests, especially live tests. For example, the earth fault loop impedence test and taking voltage measurements require contact of test probes with live terminals.

When using test leads, the manufacturer's instructions should be carefully followed and the leads should be regularly inspected for safe continued use.

Test leads, including probes or clips, should be checked to ensure they are in good order, are clean and have no signs of cracked or broken insulation. Fuses should be checked to esnure they ar of the correct type and have not been bridged.

Regulation 4(4) of the Electricity at Work Regulations (EWR) imposes a legal obligation on contractors and their employees to ensure that they are equipment for protecting persons at work (e.g. test leads, test instruments, tools, protective clothing and the like) are suitable for use, maintained in that condition and are properly used.

HSE Guidance Note GS 38 Electrical test equipment for use by electricians provides, amongst other things, design and safety requirements for test probes, test leads and test equipment sockets/terminals. GS 38 is also listed in Appendix 1 of the HSE memorandum of guidance on the EWR as a publication particularly relevant to regulations 10 (connections), 14 (work on or near live conductors) and 16 (persons to be competent to prevent injury).

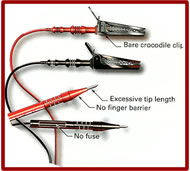

Examples of the safety design requirements in GS 38 for test leads and test probes include:

Test Leads - should:

- be adequately insulated

- be coloured so that one lead can be easily distinguished from the other

- be flexible and of sufficient capacity and duty

- be sheathed to protect against mechanical damage

- be of adequate length for use

- not have accessible exposed conductors, other than the probe tips, or have live conductors accesible to a person's finger if a lead becomes detached from a probe, indicator or instrument when in use

Test Probes - should:

- have finger barriers or be shaped to guard against inadvertent hand contact with live conductors

- be insulated to leave an exposed metal tip not exceeding metal tip not exceeding 4mm measured across any surface of the tip. Where practicable it is strongly recommended that this is reduced to 2mm or less, or that spring retractable screen probes are used

- have a suitable high braking capacity (hbc) fuses with a low current rating (usually not exceeding 500 mA) and/or a currect-limiting resistor*

- have appropriate types of tip for allowing access to the contact where dection is being made

- Although not recommended, where there is not a risk of test leads being accidently short-circuited and the fault current in them is limited by the instrument not to exceed their current-carrying capacity, fused leads may not be necessary. However, the design of the probes must conform to the requirements of GS 38 in all other respects.

Regulation 4

(from the Electricity at Work Regulations) (Part of)

Systems, work activities and protective equipment

(4) Any equipment provided for under these Regulations for the purpose of protecting persons at work on or near electrical equipment shall be suitable for the use for which it is provided, be maintained in condition suitable for that use, and be properly used.

This article is extracted from Snags and Solutions Part 3 published by the: NICEIC Group