It is not unusual for electrical contractors while carrying out electrical installation works or periodic inspection and testing to come across a Lightning Protection System.

Lightning Protection

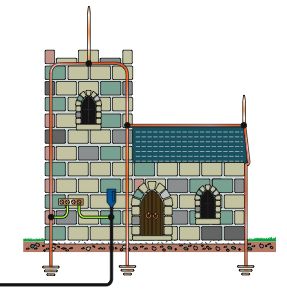

It is not unusual for electrical contractors while carrying out electrical installation works or periodic inspection and testing to come across a Lightning Protection System. A lightning Protection System (LPS) is designed to protect a structure or building and contents from damaged caused by the intensely high voltages and currents associated with a lightning strike (currents may exceed 100 kA). Whilst the design requirements of a lightning protection system may be complex, a typical LPS acts like a Faraday Cage for buildings, protecting the building and its contents from external electric fields by migrating that energy around the cage to Earth. A lightning protection system offers a lightning strike a low impedance path to Earth where enormous energy is then safely dissipated.

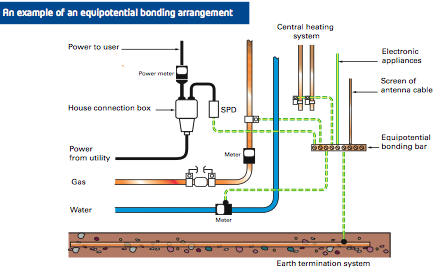

Where there are elements of the building structure and wiring that are not connected to the common means of earthing (typically the MET) there is a significant risk that induced voltages will be generated within the metalwork. Typically, therefore, a designer of a LPS will bond the LPS to the existing electrical installation via the Main Earthing Terminal (MET).

The standard which covers Lightning Protection systems is BS EN 62305-3:2006and it is worth noting that lightning protection systems are excluded from the scope of BS 7671: 2008by Regulation 110.2(ix). However there is reference to the connecting the LPS bonding conductor to the MET in Regulation 542.4.1 of BS 7671.

Regulation 411.3.1.2 (Protective equipotential bonding) requires that the connection of a lightning protection system to the protective equipotential bonding shall be made in accordance with BS EN 62305.

It is advisable that the exact position of bonding connection are agreed and determined by consultation with a lightning protection engineer/designer, due to the complexity of the requirements of BS EN 62305-3. Normally the connection should be from one of the down conductors of the lightning protection system closest to the electrical installation main earthing terminal by the most direct route available.

Bonding connections should not be made without consulting the designer/lightning protection engineer.

Bonding connections to the lightning protection system are normally made outdoors, and may involve conductors of different shapes and dissimilar metals.

Accordingly special considerations should be given to the requirement of regulation 526.1 of BS 7671 for electrical connections to provide durable electrical continuity and adequate mechanical strength and those of Regulation Group 522.5 of BS 7671: 2008 regarding measures to avoid corrosion.

So what are the requirements for connecting a lightning protection system to an electrical installation’s main earthing terminal?

While the electrical installation contractor may be required to install the bonding conductor, the choice of type and size of conductor is the responsibility of the lightning protection system designer, although the conductor must meet the relevant minimum requirements of BS 7671.

Additionally, it may be a case that the final connection to the lightning projection system is the responsibility of the lightning protection specialist and not the contractor, due account must be taken of the recommendations of BS EN 62305-3:2006 (Protection against lightning). It is advisable that the exact position of the bonding connections are determined by the lightning protection system designer, due the complexity of the requirements of BS EN 62305-3 2006. The bonding connection to the lightning protection system should not be made without consulting the designer of the lightning protection system, the system maintenance contractor or other competent person.

It is worth noting that on an Electrical Installation Certificate and an Electrical Installation Condition Report there is under ‘Particulars of the Installation Referred to’, a series of boxes detailing the pipes and steelwork which may be bonded. Whilst the LPS is not listed separately, where one exists it should be recorded in the ‘other’ box and stated as ‘Presence

of LPS’.

- For other guidance and publications please see the ELECSA website.

- Information about the ELECSA Domestic Installers schemes, visit www.elecsa.co.uk or call 0333 32