This article takes a closer look at Section 753 of BS 7671 and covers the key design and safety considerations necessary when installing electric floor heating systems.

Take a visit to a number of places in the UK, such as Housesteads (Vercovicium) Roman Fort on Hadrian’s Wall and you will see that the use of underfloor heating systems has a long history. The Roman heating system would have a furnace that would heat up air which would then be directed under a specially prepared floor: indeed, the Romans were not the first to use such a system.

The modern type of electric floor heating has been in use in the UK for some significant time and has grown in popularity over the years. Many contractors will come across this type of heating arrangement in the dwellings they work in, and it is important that they are fully aware of the specific regulations that apply to such heating systems.

Section 753

For any electrical installation the general requirements of BS 7671 must be complied with, however, BS 7671 recognises that there are instances where a special type of installation requires additional consideration; an electric floor heating system is just such a special location. Section 753 both supplements and modifies the general requirements of BS 7671 for floor and ceiling heating systems.

Protection for safety

As the protective measures of obstacles and placing out of reach, non-conducting location, earth-free local equipotential bonding and electrical separation are not permitted to be used, the contractor is left with two protective measures available to him/her – automatic disconnection of supply (ADS) and extra-low voltage provided by SELV or PELV (Regulations 753.410.3, 411 and 414).

Automatic disconnection of supply

Residual current devices (RCDs) having a rated residual operating current (IΔn) not exceeding 30 mA and an operating time not exceeding 40 ms at 5 IΔn are required to be used as the devices for fault protection of the circuits supplying floor heating installation (753.411.3.2). It should not be forgotten that each circuit also requires overcurrent protection by a circuit-breaker or fuse (Chapter 43, Protection against overcurrent).

Except for heating units of Class II construction or equivalent insulation, heating units delivered from a manufacturer without exposed-conductive-parts are to be provided with a suitable conductive covering, such as a grid with spacing not more than 30 mm, on site above the floor heating system. Where this is the case, the conductive covering must be connected to the protective conductor of the supply circuit (753.411.3.2).

Additional protection by RCD for heating equipment having Class II or equivalent insulation

For a circuit supplying heating equipment of Class II construction or equivalent insulation, additional protection by an RCD complying with the characteristics detailed in Regulation 415.1.1 is required (753.415.1) – that is, a 30 mA RCD. This protection may be provided by an RCD installed to provide fault protection in accordance with Regulation 753.411.3.2. To avoid unwanted tripping of the RCD the note attached to Regulation 753.411.3.2 advises that limiting the installation to a rated heating power of 7.5 kW at 230 V or 13 kW at 400 V downstream of a 30 mA RCD will generally avoid unwanted tripping.

Locations containing a bath or shower

For electric floor heating in a location containing a bath or shower, Regulation 701.753 permits only heating cables meeting relevant product standards, or thin sheet flexible heating elements meeting relevant equipment standards to be installed, provided that in either case these have a metal covering consisting of:

- a metal sheath or a metal enclosure, or

- a fine mesh metallic grid.

The regulation requires the metallic covering to be connected to the protective conductor of the supply circuit except where the protective measure of SELV is used for the floor heating.

External influences

No less than for every other electrical installation, the installation of a floor or ceiling heating system, including the heating units themselves, must be selected and installed taking into account the expected local external influences. This is so that persons and property will be adequately protected during its expected working life, and the equipment will operate correctly.

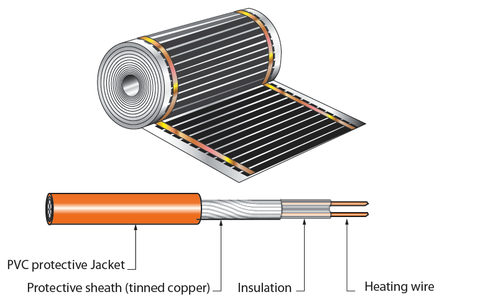

Regulation 753.512.2.5 gives minimum requirements to protect floor heating systems against external influences. For heating units installed in floors of concrete or similar material, a degree of protection not less than IPX7 with appropriate mechanical properties is required.

Protection against burns and fire

Measures should be taken to avoid floor heating systems overheating, which could lead to burns or ignition of local materials. Regulation 753.424.3.1 requires at least one of the following measures to be applied to limit the temperature and the heating zone to a maximum of 80 °C.

- Appropriate design of the heating system

- Appropriate installation of the heating system

- Use of protective devices.

Part L of the Building Regulations also places limits on temperature of heating systems to provide energy efficiency.

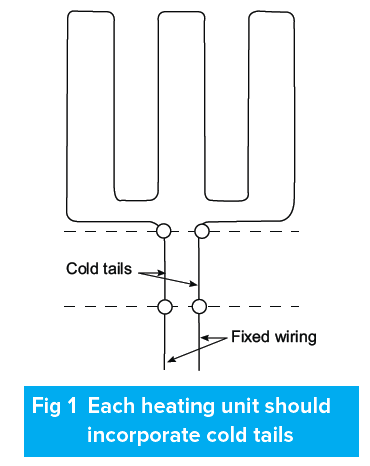

Regulation 753.424.3.1 also requires the use of cold tails or suitable terminals to connect the heating units to the electrical installation, and the heating units shall be inseparably connected to the cold tails, such as by compression jointing techniques. Heating units are normally supplied with the cold tail connected to the conductors of the sheet or cable by a factory made joint.

During fault conditions to a heating unit, such as due to penetration by a screw, high temperatures or arcs can occur. Heating units should therefore not be installed close to any local easily ignitable structural members, unless special measures to meet the requirements of Chapter 42 (Protection against Thermal Effects) are taken. Such measures could include placing the heating unit on a metal sheet, or in metal conduit or at a distance of at least 10 mm in air from the structure (753.424.3.2).

Floor heating systems should not be installed in locations where contact with skin or footwear is possible unless the surface temperature of the floor can be limited (for example, 35 °C) to protect against burns (753.423).

Applicable floor surface temperature limits may be obtained from the manufacturer or their published information. Some manufactures quote that their product ‘limits floor surface temperature to 29 °C.’

Further guidance on the installation of floor and ceiling heating systems can be found in the NICEIC and ELECSA short guide to electric floor and ceiling heating systems available from www.niceicdirect.com.

- For other guidance and publications please see the ELECSA website

- For information about the ELECSA schemes, visit www.elecsa.co.uk or call 0333 321 8220