The Solution

- be damaged during installation,

- be unsupported within the cavity deteriorate due to being in contact with cavity wall insulation,

- overheat due to the effects of the thermal insulation

- be attacked by flora or fauna, or

- provide a passage for water to be carried to the inner leaf.

Solution

Cables should normally not be installed in external cavity walls. If it is indeed required to install a cable in a cavity wall, a sheathed mineral-insulated copper sheathed (MICS) cable may be judged by the installation designer to be suitable for such a location.

Installing pvc/pvc insulated and sheathed cables in an external cavity wall is generally an undesirable practice as it is unlikely that all of the applicable requirements of BS 7671, the Building Regulations and the NHBC requirements listed below can be met.

Damage to cables during installation.

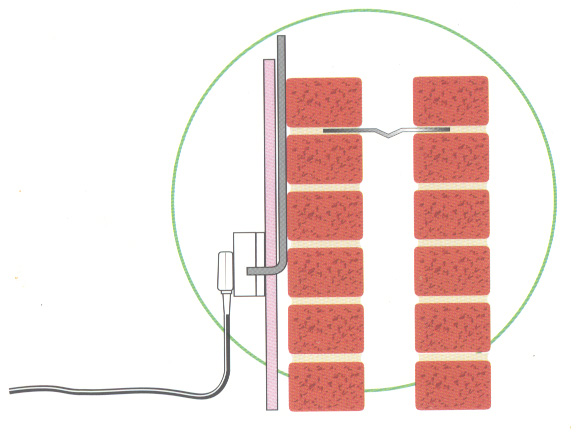

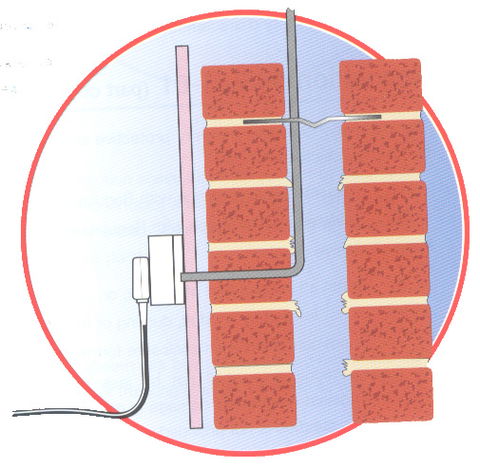

Obstructions in a cavity wall, such as metal wall ties or mortar projections, create a risk of unseen damage occurring to the cable sheath and conductor insulation during installation (Regulation 522-08-01 refers).

Strain on cables lacking support

Long unsupported vertical drops may place undue strain of the conductors, leading to damage (Regulation 522-08-04 refers).

Originally published in Snags and Solutions - part 2 wiring systems

>> Click here to buy the book.