This article aims to provide clarity on regulation group 527.2 of BS 7671.

Where a wiring system penetrates an element of building construction (floor, wall, roof, ceiling, partition or cavity barrier) having a specified fire resistance, Regulation Group 527.2 of BS 7671 requires the openings to be sealed to minimise the risk of spread of fire. Such sealing is also a legal requirement imposed by the Building Regulations in England, Wales, Scotland and Northern Ireland.

The requirements of Regulation Group 527.2 and the relevant Building Regulations are intended to preserve:

- fire separation between areas of a building, and

- structural stability of the premises in the event of fire. For example, in most domestic premises, it is the load bearing capacity of the floors that is threatened by early failure of ceiling linings due to fire.

Consequently, the requirements to seal openings apply not only for elements of building construction that sub divide the building into fire compartments (in fact many dwellings consist of only a single fire compartment); the requirements apply wherever a wiring system penetrates any element of building construction having a specified fire resistance.

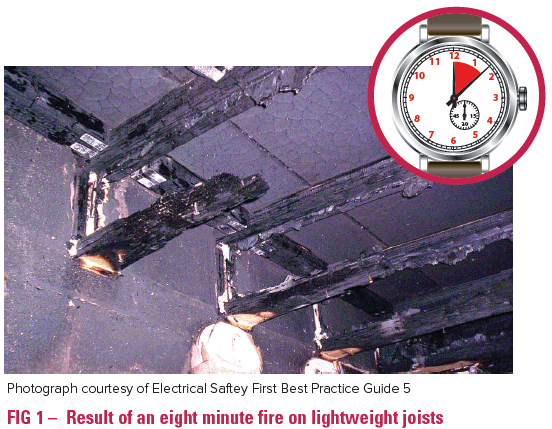

Many modern forms of engineered construction have an inherently lower level of fire resistance when compared to more traditional forms of construction, and are heavily reliant on the plasterboard or similar linings for achieving the requisite level of fire separation. As shown Fig 1, such structures may have only a short survival time if exposed to fire.

Sealing requirements of BS 7671

Regulation Group 527.2 calls for both external sealing (to fill the gaps around wiring systems) and internal sealing (within conduit, trunking, cable ducting and busbar trunking systems etc, with certain exceptions, mentioned later), at penetrations. The sealing must be such that the fire resistance of the element of building construction is restored to what it was required to be before the penetration.

The sealing arrangements are required to resist external influences to the same degree as the wiring systems with which they are used. They are also required to meet a number of further requirements, given in Regulation 527.2.4, relating to resistance to products of combustion, protection from water penetration, compatibility with wiring system materials, and mechanical stability.

Internal sealing need not be provided for conduit, trunking and cable ducting systems having an internal cross-sectional not exceeding 710 mm2 and classified by their product standards as non-flame propagating, provided they meet certain conditions given in Regulation 527.2.3, relating to tests for an ingress protection of IP33. 710 mm2 is roughly the internal cross-sectional area of a 32 mm diameter conduit. Regulation 527.2.1.1 requires temporary sealing arrangements to be in place during the erection of a wiring system as appropriate. This normally requires the use of products such as intumescent pillows or similar types of removable fire-stopping. With regard to alteration work, Regulation 527.2.1.2 calls for any sealing that has been disturbed to be reinstated as soon as practicable.

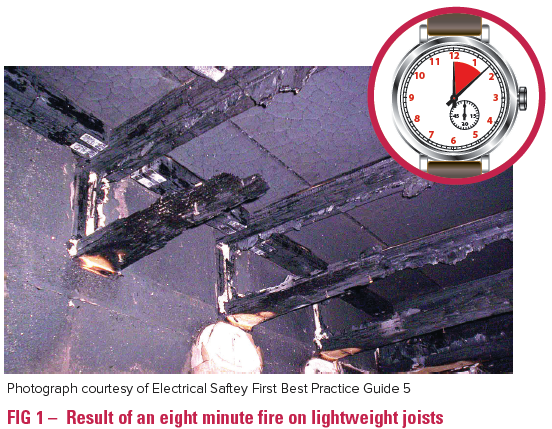

Reinstatement should use the same types of materials/components as were originally used. Mixing and matching of systems and components is not supported by manufacturers’ fire test data. If the original seal cannot be identified or sourced, the whole seal should be replaced. For external sealing, various types of fire-stopping solution can be used, including intumescent mastics, compounds, metal sleeves and fire resistant sponge-filled multi-service boxes (refer to Fig 2).

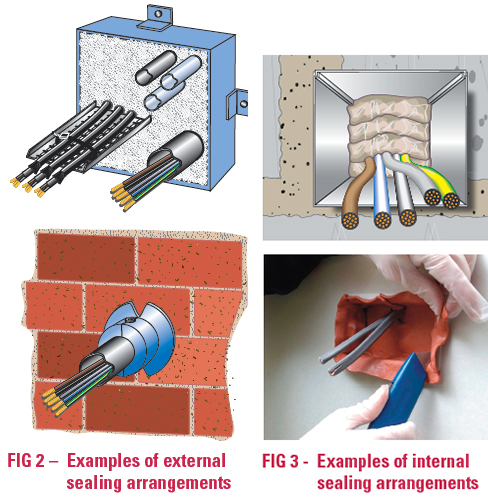

Intumescent materials have the property of expanding as they are heated, thus sealing an opening. Once expanded, the seal can last from 1 to 4 hours depending on the nature of the product and the base substrate (wall/floor etc) in which it is installed. As shown in Fig 3, internal sealing is often achieved using intumescent material. This could be in the form of mastic that can be pumped in, or as pillows for use with trunking and cable tray.

It is not advisable to use mineral wool or similar thermally insulating material for sealing purposes. Such material is likely to reduce the dissipation of heat generated in cables in normal service, thereby reducing their current-carrying capacity. For example, for cables passing through insulating material for a distance of 100 mm, the effective current-carrying capacity would be reduced by a factor of 0.78, as can be seen from Table 52.2 of Regulation 523.9.

It should be noted that although a product may carry a 'fire rating' it may not qualify as a suitable fire-stopping product. For example, expanding PU (polyurethane) foams are often not suitable as they are usually tested as linear gap seals and not tested on cable or pipe penetrations (Fire Protection (ASFP) ‘Red Book’ – Fire Stopping: Linear joint seals, penetration seals & small cavity barriers).

- For other guidance and publications please see the NICEIC website.

- For information about the NICEIC Approved Contractor or Domestic Installers schemes,visit www.niceic.com or call 0870 013 0382