Steven Bettson, Senior Technical Support Engineer of Scolmore Group answers some key questions on insulation and fitting.

When a hole is cut into a ceiling to mount a recessed downlight a potential fire hazard is created. Plasterboard ceilings have a natural ability to act as a fire barrier. In any building where people may be living the ceiling below must be fire rated. Fire rated downlights have built-in fire protection that completely seals the aperture in the event of fire in the room below to prevent the spread of fire and smoke into other areas.

The Electrical Safety Council recommends that wherever possible downlights with integral fire protection are selected for use in all ceilings where the lining that is to be penetrated is the sole means of keeping fire and heat out of the cavity. It is important that the type of downlight selected for a particular application has test evidence to support its fire performance when incorporated in a ceiling of the type into which it is being installed.

Can insulation be laid over recessed downlights?

Firstly, the downlight will need to be checked for suitability. Wiring Regulation BS 7671 559.3.1 states that every luminaire shall comply with the relevant standard for manufacture and test of that luminaire shall be selected and erected to take account of the manufacturer’s instructions.

Regulation 559.4.1 also states that in the selection and erection of a luminaire the thermal effects of radiant and convected energy on the surroundings shall be taken into account, including the minimum distance to the combustible materials, including material in the path of a spotlight beam.

What is the biggest concern?

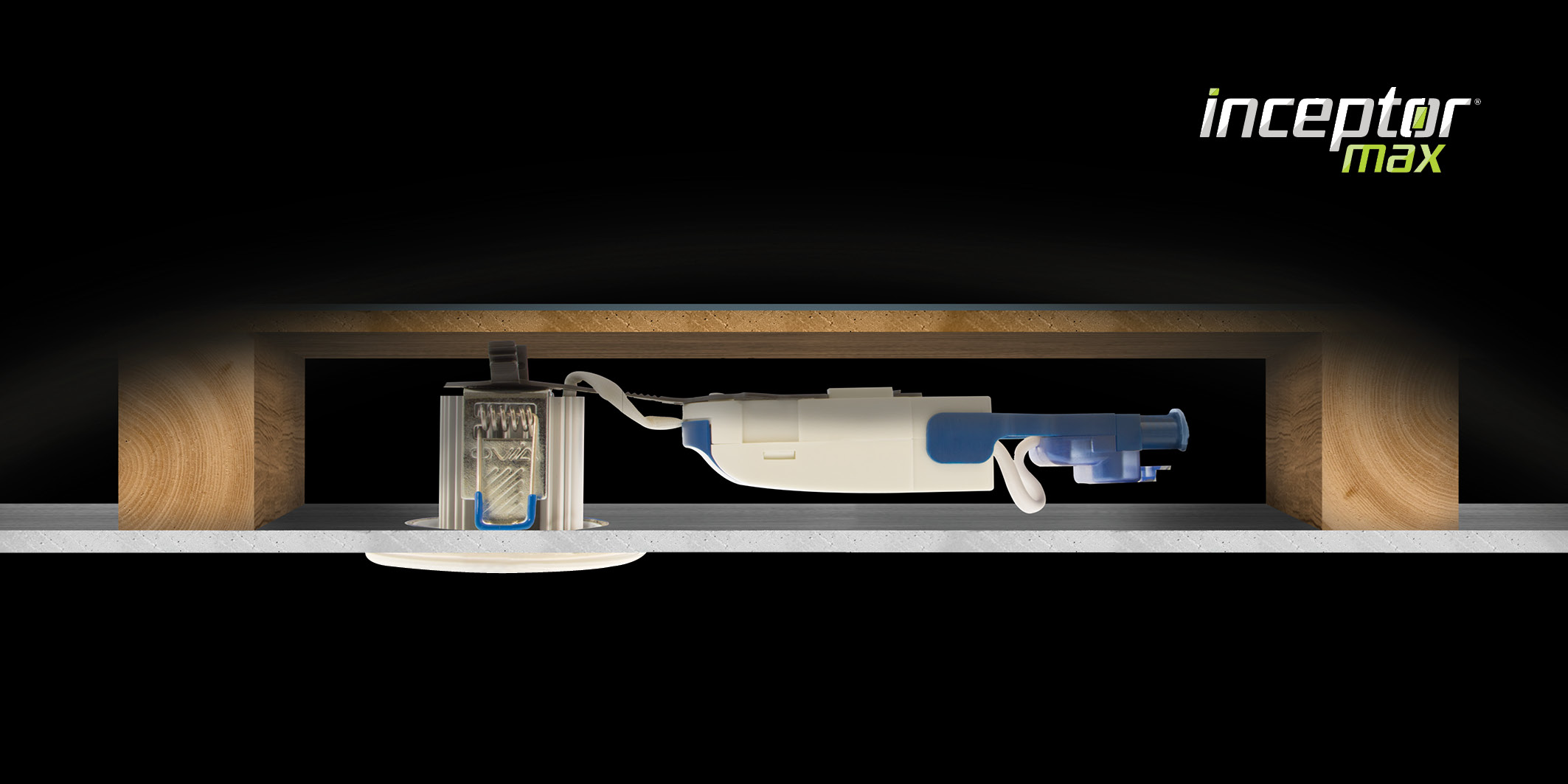

As the insulation is designed to keep the heat in, the biggest concern will be its effects on the downlight and its components. Most of new downlights on the market are fully integrated which means they combine luminaire, LED light source and driver for optimised compatibility and ease of installation. Scolmore’s Inceptor Max integrated LED downlights have the added benefit of a flexible driver mount which allows the driver to be flipped over. This allows the product to be fitted into a shallower ceiling void. This also offers an additional benefit for situations where there are concerns about using the product in particularly warm environments.

With the product fitted in its standard orientation – driver on top – heat from the LED could contribute to the temperature of the driver and, in particularly warm installations, this may lead to decreased driver life. However, if you flip the driver over so that it is mounted beside the product, the heat that rises up from the LEDs no longer rises to heat the driver, and protects the life of the driver.

SMD LEDs require lower current and create less heat than standard LEDs, which makes them perfect when space is at a premium.

The Scolmore trademark blue strip of intumescent adds an extra barrier of protection against fire by expanding to fill the gap between plasterboard and the light fitting

Protection from thermal effects is referred to in the regulations. Regulation 421.1.2 states: “Fixed electrical equipment shall be selected and erected such that its temperature in normal operation will not cause fire. This shall be achieved by the construction of the equipment or by additional protective measures taken during erection.

“The heat generated by electrical equipment shall not cause danger or harmful effects to adjacent fixed material or to material which may foreseeably be in proximity to such equipment.”

The regulations also say that where surface temperatures could cause a fire hazard to nearby materials, equipment shall be mounted to allow the safe dissipation of heat at a safe distance from nearby material on which such temperatures could be dangerous. Any means of support must be of low thermal conductance.

Regulation 421.1.4 states: “Fixed equipment causing a concentration and focusing of heat shall be at a sufficient distance from any fixed object or building element so that the object or element is not subjected to a dangerous temperature in normal conditions.”

What if I lay insulation over the top?

If insulation has been laid over the top of the downlight and the fitting has not been approved for this modification this can lead to problems.

The insulation can cause the heat sink to become ineffective, causing an increase in the junction temperature of the LED. This can also cause the LED to have a reduced lamp lifetime, prematurely fail and invalidate the warranty.

Low voltage transformers can burn out due to overheating and wiring and terminations can overheat and fail. There can be an increased risk of faults causing a fire or a hazardous scenario. Not surprisingly, this may also mean not conforming to the Wiring Regulations.

What are my options?

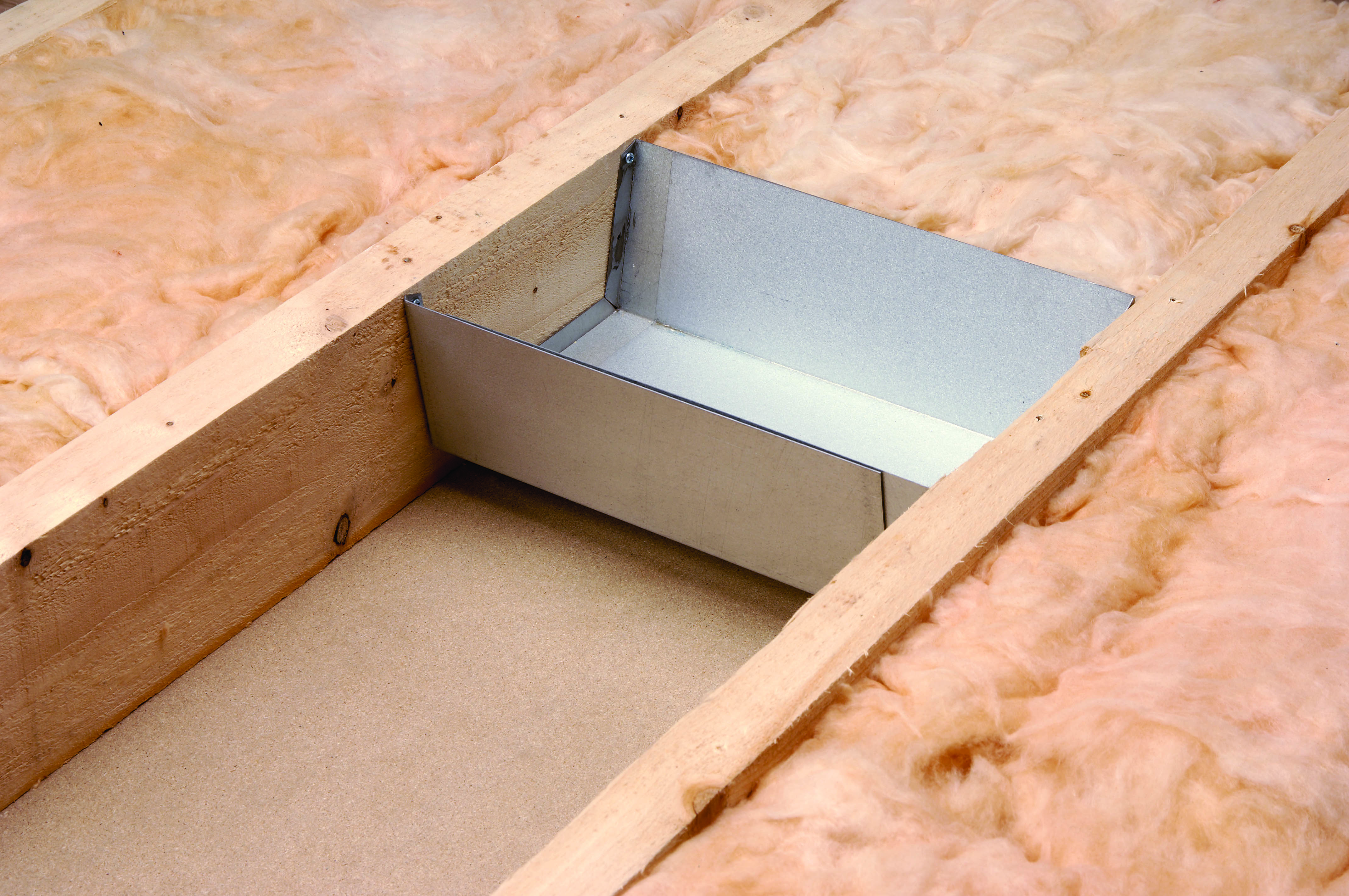

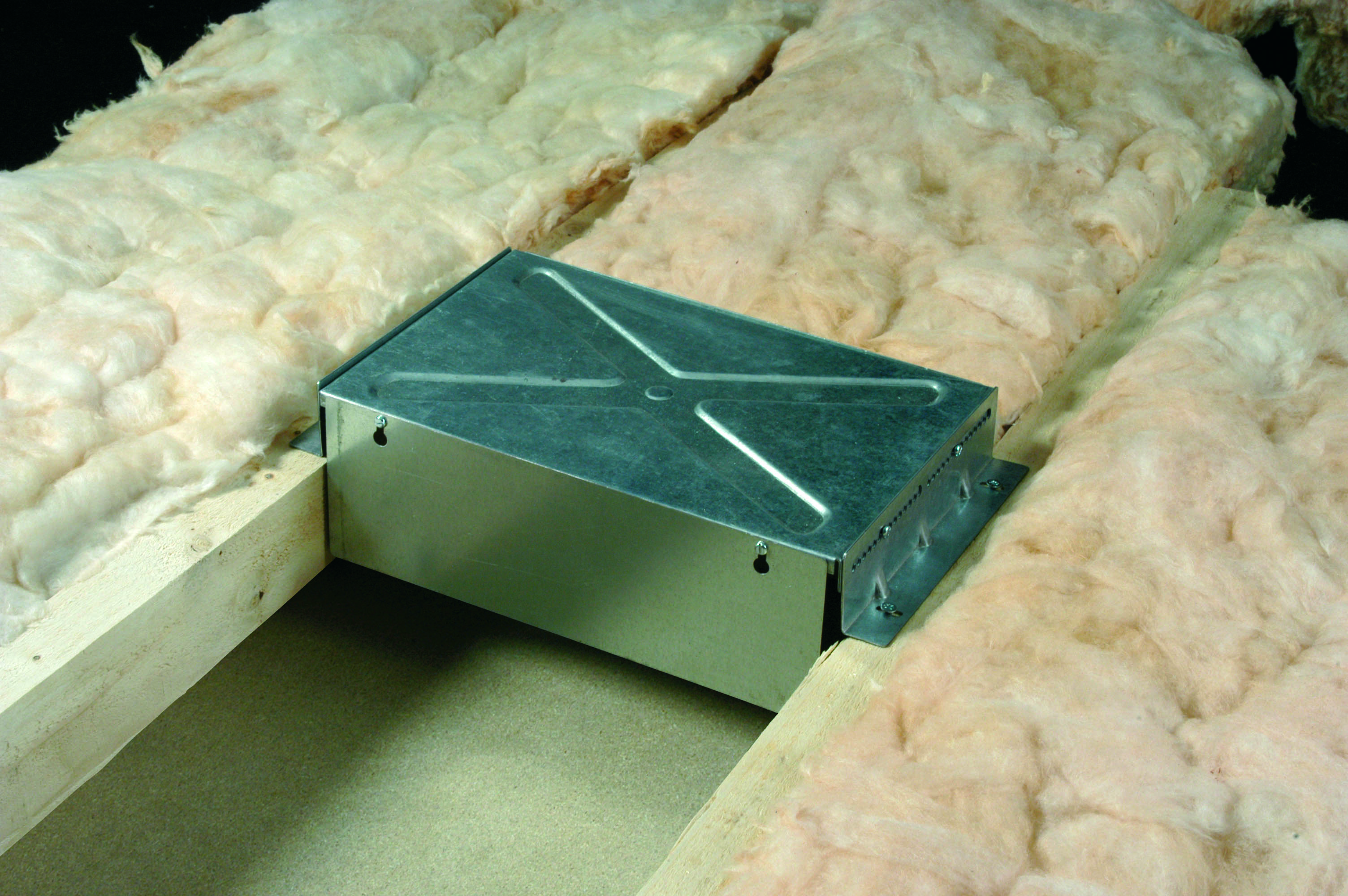

Always check with the manufacturer for their recommendations. If space is available and is required then some sort of loft cap or support for the insulation – such as the insulation support box from Scolmore – is necessary. This will allow for sufficient insulation to remain while also providing an airspace for the heat from the luminaire to dissipate.

If this is not possible, re-evaluation of the installation will need to be considered for conformity to the relevant Building Regulations and potential product selection may be needed for its designed application. Remember, correct procedure according to the appropriate Building Regulations must always be adhered to.