The UK panel building market is estimated to be around £500m. This is a sizeable sector for panel builders and it's certain that some electrical contractors have been taking a significant slice of it. So what do they build and how do they compete? James H

Today, the panel building market has many influences. These include eroding profit margins, growth in demand for clean, secure power, infrastructure investment (or lack of it), reduced assembly times, and trends towards smaller panels. The net effect is likely to be a continuing market decline. Some estimate this sector to have reduced in value by 40% over the past two years alone.

There are now estimated to be only around 300 plus panel builders in the UK, more when electrical contractors building panels are added to the mix. This is down from around 700 only four years ago. Moreover, the demand for higher control panel 'intelligence' has resulted in systems integrators gaining market share. In addition, some large electrical contractors assemble panels for their own installation projects and others. These include Balfour Kilpatrick, NG Bailey and ABB William Steward.

The argument:

Most electrical engineers and panel builders are convinced that large modern control panels - such as motor control centres (MCCs) - are too technical and too big a task for smaller electrical contractors to tackle.

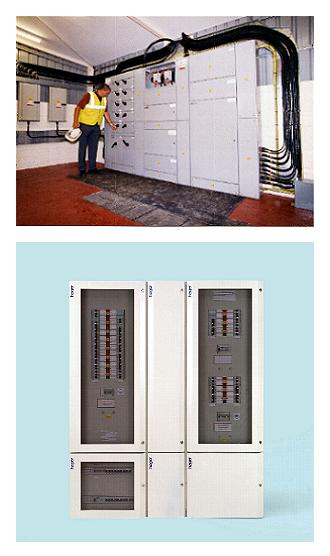

Electrical contractors often buy in proprietary panelboards from companies like Square D, Klockner Moeller, Eaton Electrical (MEM, Bill etc), Scheider Electric and Hager. Typically, they then build them up and fit protective devices such as fuse switches and/or MCBs to provide basic distribution panels. Some might then be tempted to call them Partially Type Tested, but that would be a misunderstanding of the situation and the resulting panels might well not be so. The consensus of opinion is that small to medium sized contractors would not build Form 4 panels of any type - they usually wouldn't have the knowledge and experience and certainly wouldn't find the time. But is this actually correct?

What is undeniably true is that, while electrical safety has always been of paramount importance, it is even more so now, under the weight of recent legislation and the increasingly litigious nature of the UK. The argument goes like this: 'There's a lot that can go wrong with a low-voltage panel, with severe safety implications for personnel if it does so. This is where the specialist panel builders will score, being (in theory) fully mindful of and conversant with standards and directives such as the EMC, Low Voltage and WEEE Directives and manufacturing to ISO 9000'.

Even when electrical contractors do build a properly designed panel that - on paper at least - meets the required standards, they may still have to prove it with temperature rise tests, short-circuit tests and so on. This can be very time consuming and expensive, even for experienced panel builders. Panel building is an industry cursed by small batches, and applying directives can seem difficult. Sometimes, every panel going out might need its own declaration of conformity. This would pose a very severe difficulty for electrical contractors, even if their systems were set up to cope.

A panel builder's view:

Steve Mainstone, Deputy MD of one of the UK's largest independent manufacturers - Main Systems - commented: "Outside of specific contractors products, that is modular designs, most panel manufacturers would prefer to keep the industry disciplines separate. Each to their own for very good reasons.

"Safety is a major issue in terms of technical selection of components through to qualified structures and detailed records. Risks abound in the hands of the uninitiated, where cost to fit the bills is an overriding factor in meeting the requirement for the overall panel product design", he said.

Steve Mainstone made the point that many contractors perceive that the DIY approach enhances their added value; others are not so sure in terms of lifetime costs such as special insurance product qualifications and specialist service.

MD of Main Systems, Trevor Mainstone, pointed out that whilst the government, and indeed the ECA, are promoting value for money selection as opposed to cheapest price, short termism generally rules the day and will prove expensive in the medium to longer term. Said Trevor: "The better manufacturers, like ourselves, with independently certified product, design and organisation qualifications, through to ISO 9001/2000, all to the benefit of the client, are all too often compared with competition who have next to nothing to offer in this direction. It has to be said that we rarely compete against self-build contractors."

Contractors that build panels:

Many of the large electrical and mechanical contractors are involved with panel building to some extent, though some sub-contract this out. NG Bailey, for example, owns its own top class panel building company - Switchgear and Instrumentation - though this is a major panel builder in its own right with offices spanning the world. Not all the major contracting companies make panels either. For example, a spokesperson at EMCOR Drake & Scull said: "We might make panels in-house if it made sense - it's not rocket science. But we don't have a panel building operation as a business unit and normally we sub-contract out."

To get some idea how many of the smaller electrical contractors might be involved in panel building, 20 companies were chosen completely at random and without knowing anything previously about them. Perhaps surprisingly, around 10% built some kind of control panel on a regular basis.

Acme Technical Services of Bagshot is a good example. This small to medium sized electrical contractor builds control panels. The company has specialized in building management systems (BMS) since its formation, and this led it to develop its own control panel expertise, both with new installations and upgrades. Acme says that it designs (using AutoCAD), tests, installs and commissions its own panels.

A typical panel product contains all the usual gear such as contactors, overloads, plus the BMS electronic controller. The company, which employs 30 people in total, has five staff working on the panels. Another electrical contractor, Alfa Electric (Hastings), also specializes in control panels. This company has six of its staff of 22 working full time on control panel building and it addresses the HVAC and factory automation sectors. This is the key to Alfa, which - unusually perhaps - has significant system integration and software expertise. This company, which also supplies panels to other contractors, designs using AutoCAD, builds, tests (EMC, LVD, flash tests etc), install and commissions. Its panel products typically include PLC control, as well as fieldbus systems.

When asked what advantages Alfa can provide over specialist panel builders, MD Richard Harrison said: "We offer flexibility for design and build projects - that is the key thing. We can build bespoke panels and systems for our clients and can modify them easily at a later stage if required."

Perhaps more typical of the smaller electrical contractor in this respect is Brighton-based Blair Installations. This company used to manufacture smaller control panels but stopped doing so because it was no longer cost-effective, a result of 'electricians' hourly rates going through the roof'. Another factor was that the orders for panels were too small to set up an efficient production operation. MD Steve Blair commented: "Panel building is an art form and not many electricians could do it. We used to but now we sub-contract them out to a panel builder and install them 52 weeks a year instead, mainly in the HVAC sector. We also assemble panelboards and switchboards, using mainly Eaton Electrical's MEMForm 2 equipment."

Another electrical contractor contacted, Bearsted Electrical Services of Maidstone was similar. Its MD Peter Gebhardt said: "Apart from switchboards which we build all the time, we don't really have anything to do with control panels - only once in a blue moon".

It is clear from this fairly small but probably quite representative sample that a significant number of electrical contractors go after the extra business opportunities provided by panel building. Moreover, we're not just talking about modular TP & N boards of the type supplied by companies such as Hager and Eaton Electrical (important though those are); we are talking also of quite sophisticated control panels in some cases. Even so, it would seem that the engineers and panel builders who predicted that electrical contactors would be put off by the costs and risks inherent in small batch major control panel design and manufacture were broadly right. Very few of the small to medium sized contractors were prepared to tackle those!

This article was originally published in Electrical Times magazine (Jan. 2004) by Highbury Business Communications - a Voltimum UK Media Partner.

Electrical Times

Highbury Business Communications

Nexus House, Azalea Drive, Swanley, Kent BR8 8HY

Tel: +44 (0) 20 8722 6072

Email: [email protected]

Web: www.hhc.co.uk

And: www.electricaltimes.co.uk