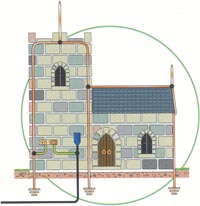

Lightning protection systems should be connected to the Main Earthing Terminal (MET). Instances are occasionally encountered of lightning protection systems not connected to the Main Earthing Terminal of the electrical installation.

This article has been extracted from Snags and Solutions Part 2 published by the NICEIC

Solution

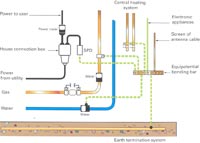

The lightning protection system must be connected to the MET of the electrical installation by main bonding conductor(s) complying with Section 544 (Regulation 411.3.1.2 refers).

Where there is a lightning protection system, due account must be taken of the recommendations of BS EN62305-3:2006 Protection against lightning (Regulation 541.3 refers).

The lightning protection system itself is, however, excluded from the scope of BS 7671 by Regulation 110.2.

It is advisable that the exact positions of bonding connections are determined by the lightning protection system designer, due to the complexity of the requirements of BS EN 62305-3.

Normally, the connection should be from the down conductor of the lightning protection system closest to the MET of the electrical installation, by the most direct route available. Bonding connections should not be made without consulting the designer of the lightning protection system, the system maintenance contractor or other competent person.

Bonding connections to a lightning protection system are normally made outdoors, and may involve conductors of different shapes and dissimilar metals. Accordingly, special consideration should be given to the requirement of Regulation 526.1 for electrical connections to provide durable electrical continuity and adequate mechanical strength, and those of Regulation Group 522.5 regarding measures to avoid corrosion.

Generally, the means of connection should be discussed and agreed with the lightning protection system designer and installer. It is often best for the actual making of a connection to the system to be carried out by the lightning protection installer, although it is still the electrical contractor's responsability to see that this is done satisfactorily.

Exceptionally, for reasons of safety, lightning protection system designers may advise that a main bonding connection should not be made to a lightning protection system. In such circumstances, the consequent departure from Regulation 411.3.1.2 must be recorded on the Electrical Installation Certificate and reference made to the last sentence of Regulation 120.3. The departure must be drawn to the customer's attention. This is permissible only where the electrical contractor has requested the main bonding connection be made, and has obtained the lightning protection system designer's written objection to the connection being made on grounds of safety.

Regulation 110.2 (part of)

The Regulations do not apply to the following installations:(ix) Lightning protection systems for buildings and structures covered by BS EN 62305

Regulation 120.3 (part of)

Any intended departure from these Parts requires special consideration by the designer of the installation and shall be noted on the Electrical Installation Certificate specified in Part 6.Regulation 411.3.1.2 (part of)

In each installation main protective bonding conductors complying with Chapter 54 shall connect to the main earthing terminal extraneous-conductive-parts including the following:(vi) Connection of a lightning protective system to the protective equipotential bonding shall be made in accordance with BS EN 62305.

Regulation 526.1 (part of)

Every connection between conductors or between a conductor and other equipment shall provide durable electrical continuity and adequate mechanical strength and protection. (Note: See Regulation 522.8 - Other mechanical stresses).Regulation 541.3 (part of)

Where there is also a lightning protection system, reference shall be made to BS EN 62305.