Not so many electrical contractors are involved in Ethernet networks, but some are, and such work will surely increase. Such networks, based upon fibre-optic cables, have been proven in use in commercial and industrial network technology sectors for a long time. Even so, high speed Ethernet (HSE), which now delivers network speeds of 40 and 100 Gigabit, means that different fibre types must be carefully considered. And they must do this without forgetting end-to-end connection costs. James Hunt reports:

The demand for ever higher Ethernet speeds comes from data centre requirements, supercomputer operators, the operators and owners of metropolitan core networks, and corporate backbones, so the IEEE 802.3ba working group introduced application standards delivering 40GbE (Gigabit Ethernet) and 100GbE performance in the local area network (LAN). Industrial and commercial applications are following suite.

There are five physical layer standards for gigabit Ethernet using optical fibre (1000BASE-X), twisted pair cable (1000BASE-T), or balanced copper cable (1000BASE-CX).

Fibre optic cabling - using a core of germania-doped silica - supports transmissions up to 10km. An outer coating protects the primary coating against mechanical damage, but metallic armour layer is sometimes included for extra protection. It is available in two basic types - multimode (OM) and single mode (OS). It comes in the following ratings:

OS1 – This, with its 1dB/km attenuation, is suitable for indoor use, or for campus building links up to 2km long.

OS2 – This type features an attenuation lower than OS1, so supports longer distances.

OM1 (62.5/125 fibre) – This type is limited by its relatively low bandwidth, and it is typically used over very short distances for higher-speed applications.

OM2 (50/125 fibre) – This type supports a higher bandwidth for high speed applications over longer distances. However, more expensive transceivers are necessary, as are - in some cases - special mode-conditioning patchcords.

OM3 (laser optimised 50/125) – This is a high performance multi-mode fibre. It is the optimum solution for transmission of 10Gbps – HSE up to 550m in length.

OM4 (laser-optimised, high bandwidth 50µm fibre) - Defined in TIA-492-AAAD, this was published at the end of 2009. It supports 125m links at 40 and 100 Gbit/s.

Types and selection

Multimode fibre – This type boasts a higher light-gathering capacity than singlemode optical fibres, and the larger core size allows the use of lower-cost LEDs or vertical-cavity surface-emitting lasers (VCSELs) operating at 850nm/1300nm wavelengths. Note that some single-mode optical fibres operate at 1310nm/1550nm – these need more expensive laser sources.

However, a disadvantage is modal dispersion limits caused by differing speeds in individual light pulse modes. This causes the light pulse to separate over distance, so receivers have difficulty in resolving individual ones and zeros. The answer is to use laser optimised multi-mode fibre (LOMMF). This eliminates fibre variations in manufacture that could affect light pulse behaviour.

Single-mode optical fibre – This type carries just a single ray of light. The typical ore diameter is 8 to 10?m, and the cladding diameter is 125µm. Single mode data rates are limited by polarisation mode and chromatic dispersion, but using the latest optical amplifiers and dispersion-compensating devices, modern dense wavelength division multiplexing (DWDM) optical systems can span thousands of kilometers at 10 Gbit/s, and several hundred kilometers at 40 Gbit/s.

Single-mode optical fibres cater for most visible light wavelengths of light and are not as limited by modal dispersion, so are less affected by distance. They also have a higher information transmission capacity than multi-mode types and only allow one light propagation mode, which makes the light easier to focus. This makes the type ideal for high-precision applications. Importantly, singlemode optical fibres are make connection simpler, which can be a crucial determinant.

Plastic optical fibre (POF) – This is conventionally made using PMMA (acrylic) as the core material, with fluorinated polymers (or silicone resins) used in the cladding, but today, a higher performance is achieved using perfluorinated polymers. Note that POF core size can be as much as a hundred times larger than glass fibres. POF typically has higher attenuation coefficients than glass fibres, 1 dB/m or higher; this limits the range.

PMMA fibres are suitable for low-speed transmission to 100m applications in smart homes, as well as some industrial (PROFIBUS, PROFINET) and automotive networks). However, fibres made from perfluorinated polymers can be used in much higher-speed applications such as data centres, building LANs and some industrial networks.

Why use POF? The answer is simple – usually it comes down to cost. Although glass fibres can be cheaper to buy than POFs, the former are far more difficult, time consuming and costly to install. POFs are far more mechanically flexible than glass fibres, so are more suitable for space-limited applications. The main disadvantage is the lower performance compared with glass fibres.

There are a number of parameters to take into account when choosing the correct optical fibre for the application. These include the distance traversed, the transmission bit-rate, and end-to-end system costs, which can be high. For the highest speeds, glass optical fibre is generally used (when copper is not), even though it is much more difficult and expensive to install.

HSE networks

The interconnection system for HSE using multi-mode fibres will be either a four-lane (8-fibres) for 40GbE, or 10-lanes (20-fibres) for 100GbE. The four-lane approach will see an estimated two-fold increase in capital costs for Ethernet-related media, with the 10-lane design introducing a four-fold increase. The physical interface for single-mode fibres will need four standard lasers with wave division multiplexing (WDM) and will cost more than multi-mode solutions. However, far less fibre will be needed.

Within the 40 and 100GbE solutions, there are four alternative cabling choices, each providing an optimum link-length deployment. OM3 or OM4 multi-mode fibres can be used, using MPO connectors. Alternatively a duplex single-mode fibre with LC connectors could be used.

Installation

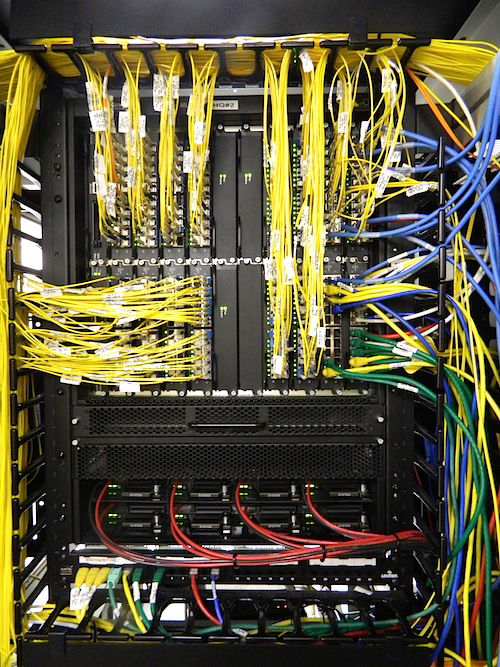

Installation methods vary. Fibre optic cables can be laid indoors in cable tray, basket or conduit exactly as with copper cables. Increasingly, blowing micro cable into pre-installed microducts is preferred. As always, final choice depends on deciding what is required for a specific application and then taking everything into account.

For networks using glass fibre-optic cables because of the long distances involved, or because of large EMC interference, users have long had to accept complex connection systems requiring training and considerable skill. Glass FOCs are assembled with difficult to use adhesive and splice processes that usually need special assembly equipment that is not ideal for use in the field. POF FOCs can be more easily assembled on-site, but are range limited.

An unusual fast connection FOC system has, therefore, been developed by Siemens to overcome such difficulties. Comprising special cables, field-assembled connectors, couplings and a termination kit, the result is glass FOCs that are well protected against mechanical and thermal loads, yet the fibre cable is as easily connected as copper.

The trick is in the glass fibres themselves. To cover distances of several kilometers and to use existing FOC devices interfaced with a wavelength of 1300nm, a 62.5µm thin core for guiding light is integrated into the fibre’s centre. The design combines simple assembly with the optical properties of a conventional multimode glass fibre. The graded design (62.5 / 200 / 230µm) allows simple plug assembly, and the 62.5µm core enables the use of the fibres with all currently used standard glass FOC interfaces, yet has a maximum bridgeable distance of 3km.

This system, says Siemens, will totally change the assembly of glass FOCs in the field, allowing even inexperienced users to assemble them. Using a simple termination kit, assembly is as easy, fast and reliable as with a copper cable. If a fault does occur, the cable can be repaired or easily extended.

Finally…

Fibre optics isn’t necessarily the only answer, even for difficult high speed applications over great distances. For example, there is the proposed copper twisted pair 40GBASE-T standard in IEEE. This could provide a considerably lower-cost option to fibre. Such a copper cable would be ideal for short-length links and for installations having many connectors.

This article was originally published in the Industrial Ethernet Book.