Shopping Cart

0 points

Distributor Selection

Select the distributor you would like to use for your shopping cart.

Distributor

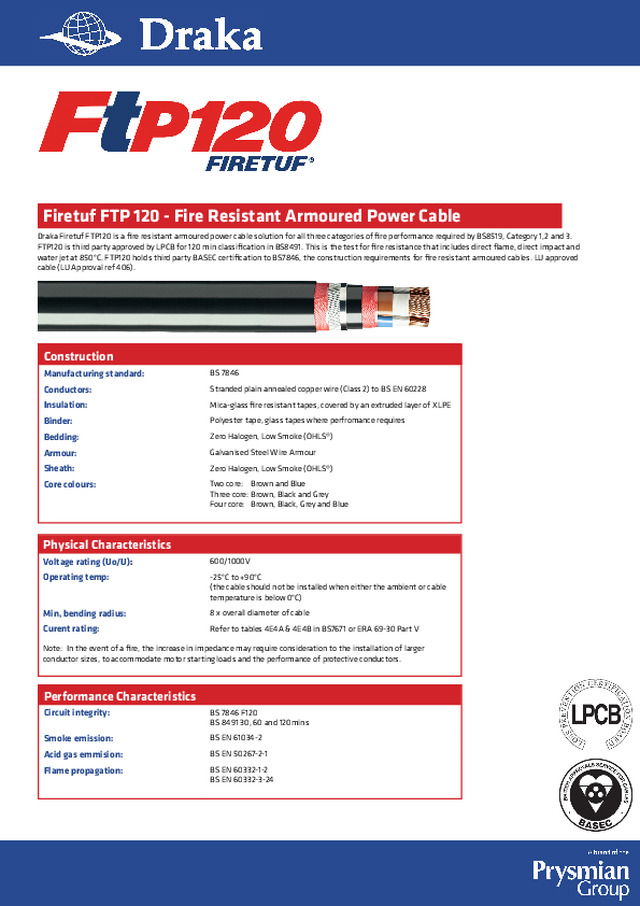

Draka - Product catalogue - Firetuf FTP 120 - Fire Resistant Armoured Power Cable

Nominal area of conductor mm² Armour wire diameter mm Approx. diameter under armour mm Approx. overall diameter mm Approx. cable weight kg/km Maximum conductor resistance Nominal area of armour mm² Maximum armour resistance at 20°C Ω /km DC at 20 C Ω /km AC at 90 C Ω /km 4 1.25 14.7 20.2 785 4.61 5.878 20 7.5 6 1.25 14.8 20.3 795 3.08 3.927 23 6.7 10 1.25 17.0 22.7 1020 1.83 2.333 39 4 16 1.25 18.3 24.2 1230 1.15 1.466 45 3.5 25 1.6 21.8 28.5 1795 0.727 0.926 62 2.5 35 1.6 24.0 31.0 2170 0.524 0.6685 68 2.3 50 1.6 25.1 32.1 2615 0.387 0.494 78 2 70 1.6 28.2 35.4 3360 0.268 0.3412 90 1.8 95 2.0 31.4 39.8 4605 0.193 0.2471 128 1.3 120 2.0 34.5 43.1 5505 0.153 0.1964 141 1.2 150 2.5 38.4 48.1 7010 0.124 0.1597 201 0.78 185 2.5 42.2 52.1 8295 0.0991 0.1284 220 0.71 240 2.5 46.9 57.1 10330 0.0754 0.0989 250 0.63 300 2.5 51.8 62.3 14425 0.0601 0.0801 269 0.58 400 2.5 57.6 68.4 15270 0.047 0.0641 304 0.52 Nominal area of conductor mm² Armour wire diameter mm Approx. diameter under armour mm Approx. overall diameter mm Approx. cable weight kg/km Maximum conductor resistance Nominal area of armour mm² Maximum armour resistance at 20°C Ω /km DC at 20 C Ω /km AC at 90 C Ω /km 4 1.25 14.7 20.2 765 4.61 5.878 19 7.9 6 1.25 14.7 20.2 760 3.08 3.927 22 7 10 1.25 15.9 21.7 875 1.83 2.333 26 6 16 1.25 17.2 22.9 1020 1.15 1.466 42 3.7 25 1.25 20.2 26.1 1325 0.727 0.926 42 3.7 35 1.6 22.5 29.3 1820 0.524 0.6685 60 2.6 50 1.6 25.8 33.0 2580 0.387 0.494 68 2.3 70 1.6 22.7 29.7 2045 0.268 0.3412 80 2 95 2.0 26.7 34.9 3465 0.193 0.2471 113 1.4 120 2.0 30.1 38.5 4150 0.153 0.1964 125 1.3 150 2.0 32.6 41.1 4845 0.124 0.1597 138 1.2 185 2.5 36.1 46.0 6235 0.0991 0.1284 191 0.82 240 2.5 40.7 50.8 7635 0.0754 0.0989 215 0.73 300 2.5 44.6 54.9 9155 0.0601 0.0801 235 0.67 400 2.5 49.8 60.4 11140 0.047 0.0641 265 0.59 2 Core FTPP2H 3 Core FTPP3H Nominal area of conductor mm² Armour wire diameter mm Approx. diameter under armour mm Approx. overall diameter mm Approx. cable weight kg/km Maximum conductor resistance Nominal area of armour mm² Maximum armour resistance at 20°C Ω /km DC at 20°C Ω /km AC at 90°C Ω /km 4 1.25 15.0 20.5 795 4.61 5.878 22 6.8 6 1.25 16.2 22.0 930 3.08 3.927 36 4.3 10 1.25 18.7 24.4 1200 1.83 2.333 42 3.7 16 1.25 20.2 26.1 1460 1.15 1.466 50 3.1 25 1.6 24.0 30.8 2150 0.727 0.926 70 2.3 35 1.6 26.6 33.6 2635 0.524 0.6685 78 2 50 1.6 29.0 36.2 3275 0.387 0.494 90 1.8 70 2.0 31.9 40.2 4555 0.268 0.3412 131 1.2 95 2.0 35.4 43.9 5770 0.193 0.2471 147 1.1 120 2.5 39.4 49.1 7380 0.153 0.1964 206 0.76 150 2.5 43.3 53.2 8720 0.124 0.1597 230 0.68 185 2.5 48.1 58.4 10535 0.0991 0.1284 255 0.61 240 2.5 53.6 64.0 13115 0.0754 0.0989 289 0.54 300 2.5 58.7 69.4 15805 0.0601 0.0801 319 0.49 400 3.15 65.6 78.1 20420 0.047 0.0641 452 0.35 4 Core FTPP4H Circular conductors, all others are shaped conductors Prysmian Group, Chickenhall Lane, Eastleigh, SO50 6YU Sales Telephone 01332 345431 Dr ak aFTP12010112013 www.drakauk.com